Bar, Neodymium & Permanent Magnets Manufacturer & Supplier in India

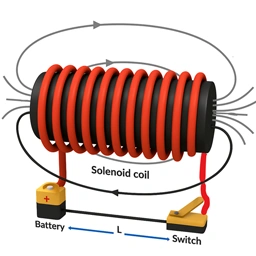

The application of powerful magnetic fields is essential across a vast spectrum of modern technologies from electric vehicle motors to high precision audio equipment. This widespread utility has positioned every proficient Bar, Neodymium & Permanent Magnets Manufacturer as a critical enabler of innovation and efficiency in the global manufacturing sector. These specialized engineering firms are dedicated to sintering and shaping rare earth elements into robust components that deliver exceptional magnetic flux density. As a leading Neodymium Magnet Supplier in India these companies utilize advanced powder metallurgy techniques to produce magnets that offer the highest strength to weight ratio commercially available. The primary function of any Permanent Magnet Manufacturer is to fabricate materials that retain their magnetic properties over long periods even under challenging environmental conditions. Among the most common shapes produced the bar magnet remains a staple for educational and industrial sorting applications making the Bar Magnet Manufacturer a key player in the supply chain. Consequently identifying a reliable Rare Earth Magnet Supplier is a strategic necessity for industries ranging from renewable energy to consumer electronics where component miniaturization and performance are paramount. A competent manufacturer employs rigorous quality assurance measures including gauss meter testing and coating thickness verification to guarantee that every unit resists corrosion and performs reliably.

Technological sophistication is the driving force behind the evolution of magnetic materials as the specific operating temperature and demagnetization resistance dictate the choice of grade. For operations that require extreme holding power in compact spaces the role of the High Strength Permanent Magnet Manufacturer is indispensable. These manufacturers design N52 grade neodymium magnets that are critical for hard disk drives and magnetic resonance imaging scanners. In the realm of heavy industry the Industrial Magnet Supplier focuses on providing magnetic separators and lifting magnets that improve safety and purity in processing lines. These powerful tools remove ferrous contaminants from food and chemical streams protecting downstream machinery and ensuring product quality. Furthermore for businesses seeking comprehensive integration of magnetic forces into their workflow the Industrial Magnetic Solutions Provider offers an invaluable service. These experts analyze the application requirements to design custom magnetic assemblies such as rotors for brushless DC motors or magnetic couplings for pumps. This holistic approach ensures that the magnetic circuit is optimized for maximum efficiency reducing energy consumption and mechanical wear while extending the operational lifespan of the final product.

Navigating the commercial market to procure these essential industrial components involves understanding the diverse supply chain options available to engineers and procurement managers. A Magnetic Products Distributor often serves as a key logistical partner for factories needing quick deployment of standard magnet shapes or immediate access to magnetic tools. These distributors play a crucial role in ensuring that fragile sintered magnets are packaged correctly and delivered safely to the facility to prevent chipping or cracking. On a different scale a Bar Neodymium Magnet Trader acts as a flexible resource for educational institutions and small workshops looking for cost effective options or specific dimensions. Traders typically maintain a diverse inventory of surplus or standard sizes allowing buyers to find immediate solutions that fit within a limited budget without the lead times associated with custom manufacturing. Whether a business chooses to engage directly with a manufacturer for a custom arc segment or works through a trader for a standard block the key to long term success lies in selecting a partner who prioritizes material consistency. A robust supply network ensures that production schedules are respected and that expert technical assistance is always at hand guaranteeing that the magnetic infrastructure remains a productive asset that drives technological advancement for the organization.