Boilers & Boiler Parts Manufacturer & Supplier in India

The efficient generation of thermal energy is the beating heart of the global industrial sector powering everything from textile dyeing units to massive petrochemical refineries. This critical operational requirement has established every competent Boilers & Boiler Parts Manufacturer as a strategic partner in the pursuit of productivity and energy conservation. These engineering firms are dedicated to designing robust pressure vessels that convert water into steam with exceptional thermal efficiency ensuring that fuel consumption is minimized while output is maximized. As a specialized Boiler Manufacturer these companies utilize high grade carbon steel and advanced welding techniques to build structures capable of withstanding extreme temperatures and pressures over decades of continuous service. The primary function of any Industrial Boiler Supplier is to provide a reliable source of process heat that drives turbines heats chemical reactors and sterilizes medical equipment. Consequently identifying a reliable Steam Boiler Manufacturer is a vital task for plant managers who aim to reduce their carbon footprint and adhere to strict environmental emission norms. A competent manufacturer employs rigorous quality assurance measures including radiographic testing of welds to guarantee the structural integrity of the vessel. By partnering with these dedicated experts industries can deploy safe and efficient heating solutions that ensure operational continuity and significant cost savings thereby securing a competitive advantage in an energy conscious market.

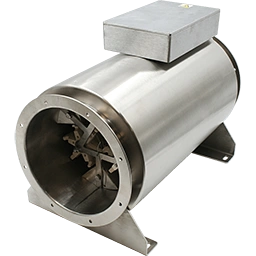

Technological sophistication is a defining characteristic of this sector as the specific pressure and steam quality requirements dictate the design of the unit. For heavy industries like power generation and sugar refining where massive amounts of steam are required at supercritical levels the role of the High Pressure Boiler Manufacturer is paramount. These manufacturers design complex water tube boilers that circulate water through heated tubes to generate high pressure steam rapidly and safely. In contrast for smaller facilities or those with limited space the expertise of a Package Boiler Supplier is indispensable. These suppliers provide pre assembled units that are mounted on skids and ready for immediate installation significantly reducing the commissioning time and civil work costs. Furthermore the efficiency of the entire system depends heavily on the quality of the ancillary hardware which is where the Boiler Equipment & Components Manufacturer plays a crucial role. These specialists fabricate essential items such as burners economizers and superheaters that recover waste heat from flue gases and improve the overall thermal efficiency of the plant. Understanding these technical nuances is essential for selecting the right equipment and a proficient manufacturer will always guide clients toward the optimal configuration for their specific fuel type and load profile.

Navigating the commercial market to maintain these critical assets involves understanding the diverse supply chain network that supports the boiler industry. A Boiler Spare Parts Supplier serves as a lifeline for facility managers ensuring the quick availability of consumable items like gaskets seals and gauge glasses. Regular maintenance is essential for safety and having a reliable source for these parts prevents minor issues from escalating into catastrophic failures. On a larger scale an Industrial Boiler Parts Distributor plays a crucial logistical role ensuring that heavy components like tube bundles and refractory materials are delivered safely to the site during planned shutdowns. These distributors often act as the local support arm for large manufacturers providing essential technical advice on part compatibility and upgrades. For businesses looking for specific valves or control instruments a Boiler Accessories Trader offers a convenient solution often stocking a wide variety of brands to suit different budgets and specifications. Whether a business chooses to engage directly with a manufacturer for a new installation or works through a trader for routine maintenance supplies the key to long term success lies in selecting a partner who prioritizes safety and quality. A robust supply network ensures that maintenance schedules are adhered to and that expert technical assistance is always available guaranteeing that the steam generation infrastructure remains a durable and safe asset for the organization.