Casting, Forging & Moulding Machines Manufacturer & Supplier in India

The manufacturing landscape of the Indian subcontinent is defined by its capacity to transform raw materials into precision engineered components that drive sectors ranging from automotive to heavy infrastructure. This fundamental industrial capability has established every prominent Casting, Forging & Moulding Machines Manufacturer as a strategic pillar of the national economy. These engineering firms are dedicated to fabricating the robust machinery required to shape metal and plastic with exceptional accuracy and structural integrity. As a specialized Casting Machine Supplier in India these companies utilize advanced thermal management systems and high grade metallurgy to build equipment that can handle molten alloys without degrading over time. The primary function of any Metal Casting Machinery Manufacturer is to provide solutions that ensure the seamless flow of liquid metal into complex dies reducing porosity and ensuring high dimensional fidelity. Furthermore the modern manufacturing environment increasingly demands a holistic approach to production problems which has given rise to the Industrial Casting, Forging & Moulding Solutions Provider. These comprehensive providers do not merely sell hardware but offer integrated systems that connect melting furnaces with forming presses and finishing stations creating a unified workflow that maximizes energy efficiency and output consistency for foundries and fabrication shops across the region.

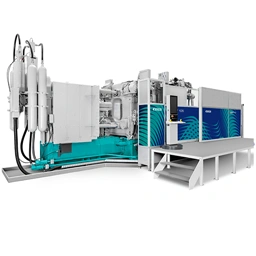

Technological sophistication is a defining characteristic of this sector as the specific material properties and desired mechanical strength dictate the configuration of the machine. In the production of high strength components like engine crankshafts and landing gear parts the role of the Industrial Forging Machine Manufacturer is paramount. These manufacturers design massive hydraulic and mechanical presses that exert immense pressure to align the grain structure of the metal thereby enhancing its fatigue resistance. To meet the high volume demands of the automotive industry many facilities rely on an Automatic Forging Machines Distributor who supplies systems integrated with robotic arms and automated billet heaters. This automation significantly reduces cycle times and removes the operator from hazardous environments. Simultaneously the polymer and rubber industries depend on the expertise of the Injection & Compression Moulding Machine Manufacturer. These specialized machines are engineered to inject molten plastic or compress thermosetting materials into intricate moulds with high repeatability. Whether creating lightweight consumer electronics or durable industrial seals the precision offered by these machines determines the final quality of the product making the choice of manufacturer a critical decision for any production manager.

Navigating the commercial market to procure these capital intensive assets involves understanding the diverse supply chain options available to industrial buyers. A versatile Moulding Machine Supplier often serves as a valuable resource for businesses looking for a wide range of tonnage options and clamping mechanisms suitable for various product sizes. For industries dealing with massive components such as automotive bumpers or water tanks the Heavy Duty Moulding Machines Supplier offers rugged equipment engineered to withstand high clamping forces and continuous duty cycles. In scenarios where budget constraints or immediate delivery are the primary concerns a Casting & Forging Equipment Trader plays a crucial role in the secondary market and in sourcing standard machinery for general engineering workshops. Traders typically maintain a diverse inventory allowing businesses to find cost effective solutions or immediate replacements to minimize downtime during unexpected failures. Whether a business chooses to engage directly with a manufacturer for a custom built solution or works through a trader for standard equipment the key to long term success lies in selecting a partner who prioritizes reliability and service. A robust supply network ensures that maintenance schedules are adhered to and that expert technical assistance is always available guaranteeing that the forming infrastructure remains a durable asset that drives productivity for years to come.