Crusher, Shredder & Presses Manufacturer & Supplier in India

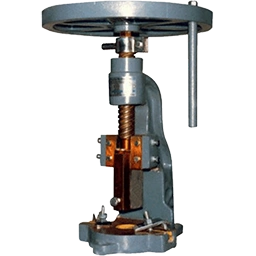

The management of solid waste and the processing of raw materials are critical challenges facing the modern industrial sector in the Indian subcontinent. This necessity has elevated the status of every proficient Crusher, Shredder & Presses Manufacturer who plays a pivotal role in the circular economy and heavy engineering industries. These manufacturing entities are dedicated to designing robust size reduction machinery that can pulverize rock or shred complex waste streams into manageable fractions. As a leading Crusher Machine Supplier in India these companies utilize high manganese steel and wear resistant alloys to build equipment that withstands the extreme abrasion inherent in mining and recycling operations. The primary function of any Industrial Shredder Manufacturer is to provide powerful dual shaft or quad shaft systems capable of tearing through tyres plastics and electronic waste with high torque and low speed. Simultaneously the expertise of a Hydraulic Press Machine Manufacturer is indispensable for the metal forming and scrap baling industries. These manufacturers engineer massive structures that exert hundreds of tons of force to compact loose scrap or shape metal sheets with precision. By partnering with these dedicated experts Indian industries can deploy efficient processing lines that maximize resource recovery and ensure operational safety thereby securing a sustainable future for their businesses.

Technological innovation is the driving force behind the efficiency of material processing plants as the physical characteristics of the feed material dictate the specific design of the machine. For operations that handle large boulders or reinforced concrete the role of the Heavy Duty Crusher Machine Supplier is paramount. These suppliers provide jaw crushers and cone crushers engineered with reinforced frames and oversized flywheels to deliver high crushing ratios without mechanical failure. In the burgeoning field of waste management the Industrial Waste Shredder Manufacturer focuses on versatility offering machines with interchangeable knives that can adapt to different materials from organic waste to hazardous drums. Furthermore the metal recycling sector relies heavily on the Scrap Crusher & Press Machine Supplier to prepare feedstock for furnaces. These integrated systems first shred the metal into uniform pieces and then densify them using high pressure presses to optimize melting efficiency. For investors seeking a comprehensive setup the Turnkey Crushing Shredding Press Solutions provider offers a holistic service. These experts take full responsibility for the project from the initial material analysis and plant layout to the final installation and automation integration ensuring that the entire line operates cohesively to meet production targets.

Navigating the commercial landscape to procure these capital intensive industrial assets involves understanding the diverse supply chain options available in the region. A Crusher & Shredder Equipment Distributor often serves as a valuable resource for construction companies and recyclers looking for quick deployment of mobile units or standard stationary plants. These distributors play a crucial logistical role ensuring that heavy components like crusher jaws and hydraulic cylinders are delivered safely to the site and that maintenance teams are available for immediate support. On the other hand a Crusher Shredder Presses Trader acts as a flexible intermediary for businesses seeking cost effective solutions or specific spare parts like screens and hammers. Traders typically maintain a network of sellers allowing facility managers to find used or refurbished equipment that fits tight budgets. However whether a business chooses to engage directly with a manufacturer for a custom built recycling plant or works through a trader for a single baler the key to long term success lies in selecting a partner who prioritizes durability and service. A robust supply network ensures that wear parts are replaced promptly and that expert technical assistance is always available guaranteeing that the reduction and compaction infrastructure remains a productive asset that drives profitability.