Industrial Belts & V Belts Manufacturer & Supplier in India

The relentless pace of modern manufacturing and heavy industry depends fundamentally on the reliable transmission of power and the efficient movement of materials which places a critical responsibility on every proficient Industrial Belts & V Belts Manufacturer & Supplier in India. These engineering powerhouses are the driving force behind sectors ranging from automotive and agriculture to mining and textiles. As a primary Industrial belts manufacturer these companies leverage advanced polymer technology and high tensile cord reinforcements to produce durable components capable of withstanding extreme torque and high rotational speeds. The core of many mechanical drive systems lies in the quality of the V belt making the role of the V belts supplier absolutely vital. These suppliers ensure that industries have access to belts that offer superior grip and minimal slippage which translates directly into energy savings and reduced operational costs. Furthermore the conveyor belts manufacturer plays a pivotal role in logistics and material handling by designing robust belts that can transport everything from crushed ore to delicate food packages. By utilizing materials like heat resistant rubber and reinforced fabric plies these manufacturers guarantee that their products can endure the rigors of continuous operation ensuring that production lines remain active and profitable.

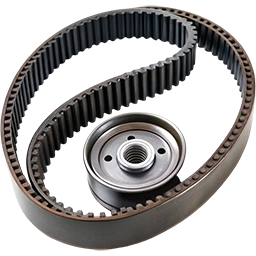

Technological diversity is essential in the power transmission market as different applications require specific belt profiles to ensure optimal performance. A timing belts manufacturer is indispensable for precision machinery where synchronous movement is required such as in robotics and automotive engines. These belts feature toothed profiles that mesh perfectly with pulleys to prevent slippage and ensure exact timing. In contrast for heavy duty applications involving rock crushers and industrial fans the heavy duty V belts distributor provides rugged solutions designed to absorb shock loads and resist stretching. These belts are often wrapped in protective fabric covers to withstand abrasion and oil exposure. The supply chain is further enhanced by the power transmission belts distributor who acts as a comprehensive resource for maintenance teams providing a wide array of flat belts ribbed belts and banded belts. For general purpose drives the rubber V belts trader serves as a flexible partner offering cost effective options for agricultural pumps and small compressors. This wide availability of specialized transmission components ensures that facility managers can find the exact belt required to optimize their machinery performance reducing the risk of premature failure and costly downtime.

Navigating the commercial landscape to procure these essential mechanical assets involves understanding the diverse sourcing channels available to procurement officers. An industrial belt supplier often acts as a strategic partner for large factories maintaining a vast inventory of standard sizes to ensure immediate availability during breakdowns. These suppliers are crucial for maintaining operational continuity by offering rapid delivery of critical replacements. On a broader scale an industrial belts trading company offers a vital bridge to global markets leveraging international networks to import high performance belts that may feature advanced materials like Kevlar or polyurethane. These trading entities provide access to premium brands that offer extended service life and higher efficiency ratings. Additionally for businesses looking to upgrade their entire drive setup the belt drive systems supplier offers a holistic service by not only supplying the belts but also the matching pulleys and tensioners. This integrated approach ensures that all components work in harmony maximizing the lifespan of the drive system. Whether a plant manager chooses to engage directly with a manufacturer for a custom conveyor setup or works through a trader for routine V belt supplies the key to long term reliability lies in selecting a partner who prioritizes product quality. A robust supply network ensures that essential transmission solutions are always within reach guaranteeing that industrial machinery remains efficient powerful and ready to meet production targets.