Industrial Mixers & Homogenizers Manufacturer & Supplier in India

The process of blending disparate ingredients into a consistent and stable product is a fundamental operation in industries ranging from pharmaceuticals and cosmetics to food processing and chemicals. This critical manufacturing requirement has established every prominent Industrial Mixers & Homogenizers Manufacturer & Supplier in India as a strategic partner for businesses aiming to achieve superior product quality. These engineering firms are dedicated to designing sophisticated machinery that facilitates the rapid dispersion of solids into liquids or the blending of multiple powders into a uniform mixture. As a specialized Industrial Mixers & Homogenizers Manufacturer these companies utilize high grade stainless steel and precision engineering to build equipment that meets stringent hygiene standards and withstands the corrosive nature of chemical additives. The primary function of any Industrial Mixer Machine Supplier is to provide a solution that ensures batch to batch consistency which is vital for maintaining brand reputation and regulatory compliance. Simultaneously the role of an Industrial Mixing Equipment Supplier extends to providing agitators and vessels that are optimized for specific viscosity levels ensuring that energy consumption is minimized while mixing efficiency is maximized. By partnering with these dedicated experts Indian manufacturers can deploy robust processing solutions that enhance reaction rates and ensure product stability thereby securing a competitive edge in the domestic and global marketplace.

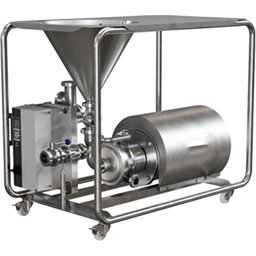

Technological sophistication is a defining characteristic of this sector as the physical properties of the materials dictate the specific type of equipment required. For applications requiring the creation of stable emulsions or the reduction of particle size to the micron level the role of the Homogenizer Machine Manufacturer is paramount. These machines utilize high pressure and shear forces to break down globules ensuring that products like milk creams and lotions remain stable without separation. In scenarios where rapid dispersion of powders into liquids is needed the expertise of a High Speed Industrial Mixer Manufacturer is indispensable. These mixers feature high shear impellers that rotate at thousands of revolutions per minute effectively breaking up agglomerates. Furthermore the Food & Chemical Homogenizer Manufacturer focuses on specific industry needs designing machines with sanitary fittings for food safety or explosion proof motors for volatile chemical environments. For sectors dealing with highly viscous materials such as adhesives or dough the Heavy Duty Industrial Mixing Machines Supplier offers rugged equipment like sigma mixers and planetary mixers engineered with powerful gearboxes to knead and blend thick compounds without stalling. Understanding these technical nuances is essential for selecting the right machinery and a proficient manufacturer will always guide clients toward the optimal technology for their specific formulation.

Navigating the commercial market to procure these essential processing assets involves understanding the diverse supply chain options available in the region. A Liquid & Powder Mixing Machine Distributor often serves as a valuable resource for businesses looking for standard equipment configurations that can be delivered and installed quickly. These distributors provide access to a wide range of vessel sizes and agitator types ensuring that factories can find a solution that fits their existing floor plan. On the other hand an Industrial Mixers & Homogenizers Trader plays a crucial role in the secondary market and in sourcing replacement parts like seals and blades which are critical for routine maintenance. Traders typically maintain a diverse inventory allowing facility managers to obtain immediate solutions to minimize downtime during unexpected equipment failures. However for comprehensive projects that require a fully integrated approach engaging with a holistic Industrial Mixing & Homogenizing Solutions Provider is often the best strategy. These providers offer end to end services from pilot plant trials and scale up calculations to final installation and automation integration. Whether a business chooses to engage directly with a manufacturer for a custom built unit or works through a trader for standard parts the key to long term success lies in selecting a partner who prioritizes performance and reliability. A robust supply network ensures that expert technical assistance is always available guaranteeing that the mixing infrastructure remains a productive asset that drives efficiency for years to come.