Insulators & Insulation Materials Manufacturer & Supplier in India

The cornerstone of energy efficiency and electrical safety in both industrial and residential sectors relies heavily on the quality of isolation materials utilized which places a significant responsibility on every proficient Insulators & Insulation Materials Manufacturer & Supplier in India. These industrial entities are the unseen guardians of power infrastructure ensuring that electricity is directed safely and that thermal energy is conserved effectively within processing plants. As a leading Insulators manufacturer these companies leverage sophisticated ceramic and polymer technologies to produce components that can withstand high voltage stress and extreme environmental conditions. The primary focus of any thermal insulation manufacturer is to develop products that minimize heat transfer thereby reducing energy consumption and lowering operational costs for factories and commercial buildings. By utilizing materials such as fiberglass rock wool and polyurethane foam these manufacturers create barriers that maintain optimal temperatures for sensitive processes. Furthermore the specialized expertise of a ceramic insulators supplier is indispensable for the power transmission sector. These suppliers provide the robust porcelain discs and posts seen on high tension towers which must endure mechanical load and electrical flashovers without failure. By adhering to rigorous international standards like IEC and ANSI these manufacturers guarantee that their products deliver long term reliability safeguarding the integrity of the national power grid and industrial machinery alike.

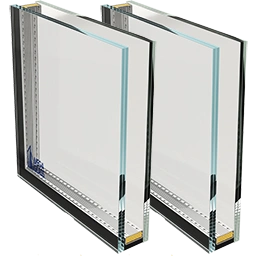

Technological advancement in material science has led to a diverse array of isolation products tailored for specific applications ranging from cryogenics to high temperature furnaces. The insulation materials supplier acts as a pivotal link in this supply chain providing a comprehensive portfolio of acoustic and thermal barriers to construction and engineering firms. For the electrical manufacturing industry the electrical insulation materials distributor plays a critical role by supplying essential components like mica tapes varnishes and insulating papers. These materials are vital for the manufacturing of motors transformers and generators where they prevent short circuits and ensure efficient operation. In the realm of heat management the heat insulation products manufacturer focuses on creating high performance cladding and lagging for pipes and boilers. These products are designed to prevent burn injuries to personnel and to stop energy loss which is a key factor in achieving sustainability goals. Additionally the industrial insulation trader serves as a resourceful partner for maintenance teams offering quick access to replacement lagging and sealants during plant shutdowns. This wide availability of specialized materials ensures that industries can maintain their safety standards and efficiency targets without facing prolonged downtime due to material shortages.

Navigating the commercial market to procure these essential engineering assets involves understanding the diverse distribution channels available to project managers and procurement officers. An electrical insulators distributor often serves as a key logistical partner for utility companies and contractors ensuring the timely delivery of bulk orders for substation projects and transmission line upgrades. These distributors manage large inventories of standard glass and polymer insulators ensuring that critical infrastructure projects remain on schedule. On a more flexible scale an insulation material wholesaler acts as a cost effective resource for construction companies and HVAC contractors looking for bulk supplies of batting and foam boards. Wholesalers typically offer volume discounts that help contractors manage project budgets effectively. For businesses looking to source hard to find composite materials or specific imported brands the insulation trading company offers a vital service by leveraging global connections to locate niche products. Whether a plant manager chooses to engage directly with a manufacturer for a custom order of furnace lining or works through a trader for routine maintenance supplies the key to operational success lies in selecting a partner who prioritizes material certification. A robust supply network ensures that high quality isolation materials are always available guaranteeing that the infrastructure remains safe efficient and capable of meeting the demands of modern industry.

Pulux Industries Private Limited

Meerut, Uttar Pradesh - 250002Sandwich panel price per square meter, Sandwich panels manufacturer, Best PUF Panels, PUF panels for walls supplier, Polyurethane foam insulation sheets, Stainless steel sandwich panels for pharma, Industrial sandwich panels supplier...

Pulux Industries Private Limited

Meerut, Uttar Pradesh - 250002Customized PUF Sandwich Panel Manufacturers in Delhi, PUF Sandwich Panel Manufacturers in Delhi, PUF Insulated Wall Panel Manufacturers in Delhi, Top PUF Panel Dealers in Delhi, PUF Sandwich Panel Supplier in Delhi, PUF Sandwich Panels Traders in Delhi, PUF Labor Huts Manufacturers in Delhi, PUF Meeting Halls Manufacturers in Delhi, PUF Shops Manufacturers in Delhi...

Viraat Industries

Bengaluru, Karnataka - 560025UPVC Roofing Sheet Manufacturer in Bengaluru New Delhi, Best UPVC Roofing Sheet Manufacturer in Bengaluru New Delhi, Top UPVC Roofing Sheet Manufacturer in Bengaluru New Delhi, High Quality, Modern UPVC Roofing Sheet Manufacturer in Bengaluru New Delhi , , ...

Omkar Puf Insulation Pvt Ltd

Thane, Maharashtra - 400701PUF Panel Manufacturer in Thane Maharashtra, Best PUF Panel Manufacturer in Thane Maharashtra, Top PUF Panel Manufacturer in Thane Maharashtra, High Quality PUF Panel Manufacturer in Thane Maharashtra, Reliable PUF Panel Manufacturer in Thane Maharashtra , , ...

Cactus Profiles Pvt Ltd

Noida, Uttar Pradesh - 201301PUF Sheets Manufacturer in Noida Uttar Pradesh, Best PUF Sheets Manufacturer in Noida Uttar Pradesh, Top PUF Sheets Manufacturer in Noida Uttar Pradesh, High Quality PUF Sheets Manufacturer in Noida Uttar Pradesh, Affordable PUF Sheets Manufacturer in Noida Uttar Pradesh , , ...

Technopuff Solutions Pvt Ltd

Ghaziabad, Uttar Pradesh - 201204PUF Panel Sheet Manufacturer in Ghaziabad Pradesh, Best PUF Panel Sheet Manufacturer in Ghaziabad Pradesh, Top PUF Panel Sheet Manufacturer in Ghaziabad Pradesh, High Quality PUF Panel Sheet Manufacturer in Ghaziabad Pradesh, Affordable PUF Panel Sheet Manufacturer in Ghaziabad Pradesh, , ...

Engko Engineering Company

North Delhi, Delhi - 110006PUF Panel Sheets Manufacturer in Khari Baoli New Delhi, Best PUF Panel Sheets Manufacturer in Khari Baoli New Delhi, Top PUF Panel Sheets Manufacturer in Khari Baoli New Delhi, High Quality PUF Panel Sheets Manufacturer in Khari Baoli New Delhi, Affordable PUF Panel Sheets Manufacturer in Khari Baoli New Delhi, , ...

Metecno India Pvt Ltd

Chennai, Tamil Nadu - 600029Roof Panel Manufacturer in Chennai Tamil Nadu, Best Roof Panel Manufacturer in Chennai Tamil Nadu, Top Roof Panel Manufacturer in Chennai Tamil Nadu, Reliable Roof Panel Manufacturer in Chennai Tamil Nadu, High Quality Roof Panel Manufacturer in Chennai Tamil Nadu , , ...

Uma Signature Puf Panel Llp

Vadodara, Gujarat - 391210Sandwich Panels Manufacturer in Vadodara Gujrat, Best Sandwich Panels Manufacturer in Vadodara Gujrat, Top Sandwich Panels Manufacturer in Vadodara Gujrat, High Quality Sandwich Panels Manufacturer in Vadodara Gujarat, Affordable Sandwich Panels Manufacturer in Vadodara Gujarat, , ...

Epack Polymers Pvt. Ltd

Gautam Buddha Nagar, Uttar Pradesh - 201306Industrial Shed Manufacturer in Noida Uttar Pradesh, Best Industrial Shed Manufacturer in Noida Uttar Pradesh, Top Industrial Shed Manufacturer in Noida Uttar Pradesh, Reliable Industrial Shed Manufacturer in Noida Uttar Pradesh, High Quality Industrial Shed Manufacturer in Noida Uttar Pradesh, , ...

Nature Wood House

West Delhi, Delhi - 110063Steel Fabrication Services in Paschim Vihar New Delhi, Best Steel Fabrication Services in Paschim Vihar New Delhi, Top Steel Fabrication Services in Paschim Vihar New Delhi, Affordable Steel Fabrication Services in Paschim Vihar New Delhi, High Quality Steel Fabrication Services in Paschim Vihar New Delhi , , ...

Maks Engineering Co

Ghaziabad, Uttar Pradesh - 201010PUF Panels Manufacturer in Ghaziabad Uttar Pradesh, Best PUF Panels Manufacturer in Ghaziabad Uttar Pradesh, Top PUF Panels Manufacturer in Ghaziabad Uttar Pradesh, High Quality PUF Panels Manufacturer in Ghaziabad Uttar Pradesh, Reliable PUF Panels Manufacturer in Ghaziabad Uttar Pradesh, , ...

Ajay Enterprises

Coimbatore, Tamil Nadu - 641002Metal Composite Panels in Coimbatore, ACP Sheet Manufacturer in Coimbatore, Aluminium Composite Panels in Coimbatore, PVDF Coated Panels in Coimbatore, Architectural Facade Panels in Coimbatore, Alloy 3003 ACP Sheets in Coimbatore, Durable Building Panels in Coimbatore...