Pharmaceutical Machinery Manufacturer & Supplier in India

The pharmaceutical sector in the Indian subcontinent is recognized globally as a powerhouse of generic drug production and high quality formulation development. This immense industrial capability is supported by a robust network of engineering firms where every prominent Pharmaceutical Machinery Manufacturer plays a critical role in ensuring public health. These specialized companies are dedicated to designing and fabricating sophisticated equipment that meets the stringent Good Manufacturing Practice standards required by regulatory bodies worldwide. As a leading Pharmaceutical Equipment Supplier in India these entities provide the essential hardware that transforms active pharmaceutical ingredients into safe and effective dosage forms. The primary function of any Pharma Processing Machinery Manufacturer is to build systems that ensure absolute purity and consistency whether mixing powders for tablets or blending liquids for syrups. Consequently identifying a reliable Industrial Pharmaceutical Equipment Manufacturer is a strategic necessity for drug makers who aim to maintain compliance and maximize production efficiency. A competent manufacturer employs rigorous quality assurance measures including material traceability and validation protocols to guarantee that every machine part contacting the drug is inert and hygienic. By partnering with these dedicated experts Indian pharmaceutical companies can deploy precise manufacturing solutions that ensure patient safety thereby securing a competitive advantage in the highly regulated global market.

Technological sophistication is a defining characteristic of this sector as the specific dosage form dictates the complexity of the machine. For solid dose production the role of the Tablet & Capsule Manufacturing Machine Supplier is paramount. These suppliers provide high speed rotary tablet presses and automatic capsule fillers that can produce millions of units per shift with uniform weight and disintegration properties. In the critical area of final presentation the expertise of a Pharma Packaging Machinery Manufacturer is indispensable. These manufacturers design blister packing machines and cartoning systems that protect the product from moisture and contamination while ensuring tamper evidence. Furthermore the drive towards modernization has elevated the importance of the Automatic Pharmaceutical Machines Supplier who provides integrated lines with PLC controls and remote monitoring capabilities. This automation minimizes human intervention reducing the risk of cross contamination and ensuring data integrity for regulatory audits. For complex projects requiring a holistic approach engaging with a provider of Turnkey Pharmaceutical Machinery Solutions is often the best strategy. These experts manage the entire project lifecycle from cleanroom layout design to equipment installation and validation ensuring seamless integration of all process steps.

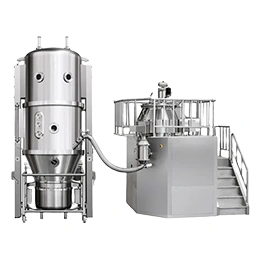

Navigating the commercial market to procure these high value assets involves understanding the diverse supply chain options available in the region. A Pharmaceutical Machinery Trader often serves as a valuable resource for small to medium enterprises looking for cost effective solutions or quick availability of standard auxiliary equipment like laboratory stirrers and inspection belts. Traders typically maintain a diverse inventory allowing facility managers to find immediate solutions to minimize downtime during maintenance or capacity expansion. On a larger scale a Pharmaceutical Machinery Distributor plays a crucial logistical role ensuring that heavy granulation lines and fluid bed dryers are delivered safely to the site and that qualification documents are provided promptly. These distributors often act as the local support arm for large international brands providing essential after sales service and spare parts. Whether a business chooses to engage directly with a manufacturer for a custom built production line or works through a trader for standard units the key to long term success lies in selecting a partner who prioritizes compliance and validation support. A robust supply network ensures that maintenance schedules are adhered to and that expert technical assistance is always available guaranteeing that the pharmaceutical manufacturing infrastructure remains a compliant and productive asset.