Rubber Processing & Tyre Machinery Manufacturer & Supplier in India

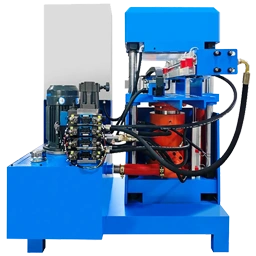

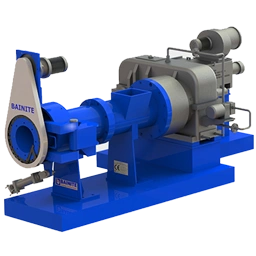

The global automotive and industrial sectors rely heavily on the consistent quality of rubber components and tyres which serves as the foundation for modern transportation and logistics. This critical dependency has elevated the role of every proficient Rubber Processing & Tyre Machinery Manufacturer who is dedicated to engineering robust systems for transforming raw natural and synthetic rubber into durable finished goods. As a prominent Rubber Processing Machine Supplier in India these companies utilize high grade alloys and advanced thermal management technologies to fabricate equipment that can withstand the intense heat and friction generated during the compounding process. The heart of any rubber plant lies in the preparation of the material where the expertise of a Rubber Mixing & Milling Machine Supplier is indispensable. These suppliers provide heavy duty dispersion kneaders and two roll mills that ensure the uniform distribution of carbon black and chemical additives within the rubber matrix. For operations handling massive volumes of stiff compounds the Heavy Duty Rubber Processing Machinery Manufacturer offers rugged intermixers and crackers designed with reinforced rotors and powerful gearboxes to process the material without mechanical failure ensuring that the compound achieves the necessary physical properties for its intended application.

Technological advancement is the driving force behind the efficiency of modern tyre plants as the complexity of tyre construction dictates the sophistication of the machinery involved. A specialized Tyre Manufacturing Machinery Manufacturer plays a pivotal role in this ecosystem providing the equipment required for building the tyre carcass applying the tread and curing the final product under high pressure. In the realm of continuous profile production the Rubber Extrusion & Calendaring Machine Supplier is essential for creating consistent sheets and sidewalls. These machines are engineered with precision temperature controls and variable speed drives to maintain strict dimensional tolerances which is vital for the balance and safety of the final tyre. Furthermore the industry is witnessing a significant shift towards automation led by the Automatic Tyre Processing Machine Manufacturer. These manufacturers design intelligent tyre building machines and curing presses that minimize human intervention and reduce cycle times. This automation not only enhances production speed but also improves the uniformity of the tyre ensuring that every unit meets stringent international safety standards and performance criteria required by global automotive brands.

Navigating the commercial landscape to procure these capital intensive industrial assets involves understanding the diverse supply chain options available to facility managers. An Industrial Rubber Processing Equipment Distributor often serves as a key logistical partner for factories needing quick deployment of auxiliary units or standard processing lines. These distributors play a crucial role in ensuring that heavy machinery is delivered safely to the site and that essential spare parts are available to prevent costly production halts. On a different scale a Rubber & Tyre Machinery Trader acts as a flexible resource for businesses seeking cost effective used equipment or specific components like hydraulic seals and heating elements. Traders typically maintain a network of sellers allowing entrepreneurs to find immediate solutions that fit within limited budgets. However for investors looking to establish a state of the art facility the Turnkey Rubber & Tyre Machinery Solutions provider offers a comprehensive service. These experts manage the entire project from plant layout design and utility planning to equipment installation and final commissioning ensuring that all processing stages from mixing to curing operate in perfect synchronization. A robust supply network ensures that maintenance schedules are adhered to and that expert technical assistance is always available guaranteeing that the rubber processing infrastructure remains a productive asset that drives profitability.