Stamping Tools & Stamping Machine Manufacturer & Supplier in India

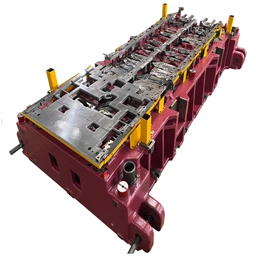

The backbone of the automotive and consumer electronics sectors relies heavily on the ability to shape metal sheets with high speed and accuracy which places a monumental responsibility on every proficient Stamping Tools & Stamping Machine Manufacturer & Supplier in India. These industrial engineering firms are the driving force behind mass production enabling the rapid fabrication of car body panels appliance casings and intricate electrical contacts. As a primary Stamping tools manufacturer these companies utilize high grade tool steel and carbide to fabricate durable dies that can withstand millions of cycles without losing dimensional accuracy. The manufacturing process involves precision grinding and wire cut EDM to ensure that the punch and die clearances are perfect which is critical for producing burr free parts. A specialized Industrial stamping machines manufacturer focuses on designing robust frames that resist deflection under tonnage. These manufacturers produce a range of equipment from high speed mechanical presses to advanced servo presses that offer programmable slide motion for complex forming operations. Furthermore the Hydraulic stamping machine manufacturer plays a pivotal role in heavy duty applications where deep drawing is required. Their machines provide consistent force throughout the stroke allowing for the forming of thick metal plates and deep vessels without tearing the material. By adhering to international safety and quality standards these manufacturers guarantee that their equipment delivers reliable performance maximizing uptime and profitability for fabrication shops.

The diversity of metal forming applications drives the demand for a wide array of machinery and specialized tooling. A reliable Stamping machine supplier acts as a strategic partner for facility managers providing everything from compact C frame presses for small parts to massive transfer presses for automated production lines. In the realm of sheet metal fabrication the Sheet metal stamping machines supplier provides essential equipment that handles various material gauges and widths. These suppliers ensure that the machines are equipped with modern feeding and straightening systems to automate the raw material input increasing overall throughput. For operations requiring high impact force for cutting and piercing the Power press stamping trader offers both mechanical and pneumatic clutch presses. These traders often stock refurbished and new units providing flexible options for businesses with varying capital budgets. The supply chain is further supported by the Precision stamping tools distributor who ensures that specialized die sets and standard components like punches and springs are readily available. This availability is crucial for maintenance teams as immediate access to replacement tool parts prevents prolonged production stoppages. Additionally the distributor helps in selecting the right coating for the tools such as titanium nitride to extend tool life when stamping abrasive materials like stainless steel.

Navigating the commercial market to procure these essential manufacturing assets involves understanding the diverse sourcing channels available to procurement officers. A Metal stamping tools distributor often serves as a comprehensive logistics partner for press shops maintaining a vast inventory of standard die components to ensure just in time delivery. These distributors are key to maintaining operational continuity by offering rapid supply of critical spares. On a larger scale the Stamping equipment wholesaler offers a cost effective solution for factories looking to expand their capacity. Wholesalers provide significant volume discounts on auxiliary equipment like decoilers and feeders helping businesses manage their expansion costs effectively. For companies seeking to source specialized imported technology or specific brand presses the Stamping tools trading company offers a vital bridge to global markets. These trading entities leverage international networks to import high precision dies and advanced press technology that may not be manufactured locally ensuring that Indian industries remain competitive on the world stage. Whether a production manager chooses to engage directly with a manufacturer for a custom progressive die or works through a trader for routine press maintenance supplies the key to manufacturing success lies in selecting a partner who prioritizes engineering excellence. A robust supply network ensures that high quality stamping solutions are always within reach guaranteeing that industrial production remains efficient accurate and scalable.