Wire Drawing & Cabling Machines Manufacturer & Supplier in India

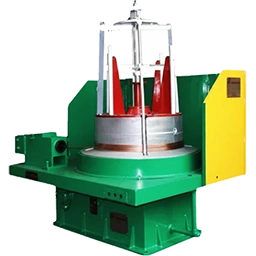

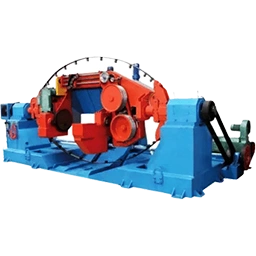

The continuous expansion of the power and telecommunications sectors in the Indian subcontinent is underpinned by the robust supply of high quality conductors and cables. This critical infrastructure requirement has established every prominent Wire Drawing & Cabling Machines Manufacturer & Supplier in India as a strategic pillar of national development. These engineering firms are dedicated to designing sophisticated machinery that elongates metal rods into fine wires with precise diameters and uniform surface finish. As a specialized Wire Drawing & Cabling Machines Manufacturer these companies utilize heavy duty gearboxes and wear resistant capstans to build equipment that can withstand the immense tension and friction involved in the drawing process. The primary function of any Wire Drawing Machine Supplier is to provide a system that reduces the cross section of copper or aluminum rods while improving their tensile strength through work hardening. Simultaneously the role of a Cable Making Machine Manufacturer involves engineering complex stranding and extrusion lines that bundle these wires and apply insulation layers. By partnering with these dedicated experts Indian wire and cable producers can deploy robust manufacturing solutions that ensure high electrical conductivity and mechanical durability thereby securing a competitive advantage in the global market.

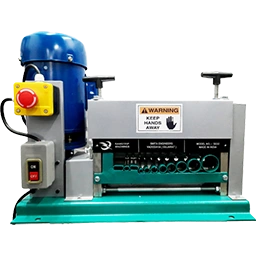

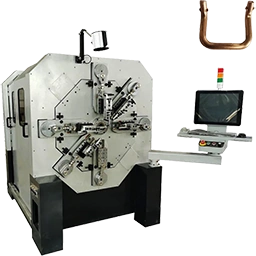

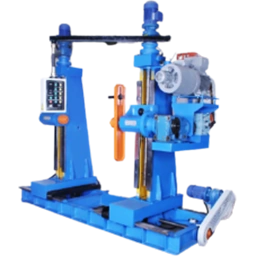

Technological sophistication is a defining characteristic of this sector as the specific metal properties and desired wire gauge dictate the configuration of the machine. For operations processing non ferrous metals which are the backbone of electrical transmission the expertise of a Copper & Aluminum Wire Drawing Machine Manufacturer is paramount. These manufacturers design machines with specialized lubrication systems and annealing sections to prevent wire breakage and ensure ductility. In the realm of high speed production the role of the Automatic Wire Drawing Machine Supplier is indispensable. These suppliers provide multi pass machines integrated with continuous resistance annealers and dual spoolers allowing for non stop operation and significantly higher throughput. Furthermore for sectors dealing with high strength steel wires for construction or tire reinforcement the Heavy Duty Wire Drawing Machinery Supplier offers rugged equipment engineered with powerful motors and reinforced frames to handle the extreme loads. An Industrial Wire Drawing Machinery Manufacturer often provides comprehensive lines that include descaling pickling and coating units ensuring that the raw material is perfectly prepared before it enters the drawing dies. Understanding these technical nuances is essential for selecting the right equipment and a proficient manufacturer will always guide clients toward the optimal technology for their specific material and production volume.

Navigating the commercial market to procure these capital intensive assets involves understanding the diverse supply chain options available in the region. A Wire Drawing & Cabling Machine Trader often serves as a valuable resource for businesses looking for cost effective solutions or quick availability of auxiliary equipment like pointing machines and butt welders. Traders typically maintain a network of sources allowing factory managers to find immediate replacements or used machinery to minimize downtime during capacity expansion. On a larger scale a Wire & Cable Processing Equipment Distributor plays a crucial logistical role ensuring that massive extrusion lines and stranding cages are delivered safely to the installation site. These distributors often act as the local support arm for large international brands providing essential after sales service and spare parts availability. However for comprehensive projects that require a strategic approach engaging with a holistic Wire & Cable Manufacturing Equipment Supplier is often the best path. These suppliers offer end to end consultancy including plant layout design and process optimization. Whether a business chooses to engage directly with a manufacturer for a custom built drawing line or works through a trader for standard components the key to long term success lies in selecting a partner who prioritizes machine uptime and product quality. A robust supply network ensures that maintenance schedules are adhered to and that expert technical assistance is always available guaranteeing that the cable manufacturing infrastructure remains a productive asset.