Choosing Between Automatic and Semi Automatic Production Units

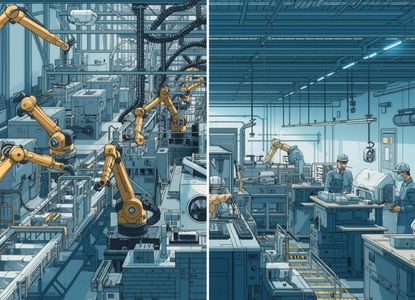

Deciding between fully automated technology and semi automated systems is a pivotal choice that shapes the operational workflow of an incense factory. An Automatic Agarbatti Making Machine Supplier will advocate for the former, highlighting the incredible efficiency and labor saving potential of these units. Automatic machines are engineering marvels that are designed for high volume production. They function with a continuous feeding mechanism where the operator simply needs to load the bamboo sticks into a hopper and the masala into a mixer. The machine takes over from there, coating, finishing, and counting the sticks with high precision. This setup is ideal for established businesses that have a steady demand and need to produce tons of incense daily. The consistency provided by automatic machines is unmatched, ensuring that every stick burns for the exact same duration and releases fragrance uniformly. However, these machines require a stable power supply and a dust free environment to function optimally, which are factors that factory owners must prepare for in advance.

On the other end of the spectrum lies the Semi Automatic Agarbatti Making Machine, which remains a favorite among many producers for its simplicity and ruggedness. unlike their fully automatic counterparts, these machines require an operator to manually feed the sticks into the rolling mechanism. While this increases the labor requirement slightly, it also offers greater control over the production process. Semi automatic machines are generally more forgiving of irregularities in the bamboo sticks and are easier to repair if a mechanical issue arises. They are also significantly cheaper, making them an attractive option for startups or factories located in areas where skilled technical maintenance for complex electronics is hard to find. Additionally, the role of a Raw Agarbatti Making Machine Manufacturer is crucial in this supply chain. These manufacturers produce heavy duty machines that create the base unscented sticks. Whether you use an automatic or semi automatic finishing machine, the quality of the raw stick produced by these primary units dictates the final texture of the product. Investing in a high quality raw stick machine ensures that the foundation of your product is strong.

Ultimately, the choice between automatic and semi automatic depends on your specific business goals, budget, and infrastructure. If your aim is rapid expansion and you have the capital to invest in high end infrastructure, partnering with a top tier Automatic Agarbatti Making Machine Supplier is the logical path. It positions your business for mass market dominance. Conversely, if you value flexibility, lower initial capital expenditure, and a hands on approach to quality control, the semi automatic route offers a safe and profitable entry point. Many successful manufacturers actually employ a hybrid strategy, using automatic machines for their best selling standard products and semi automatic ones for premium or irregular sized sticks. Regardless of the choice, the Indian machinery market offers excellent options in both categories. By carefully evaluating the technical specifications and matching them with your production targets, you can build a manufacturing line that is both efficient and resilient, ready to meet the diverse needs of customers worldwide.