Driving Efficiency with Automated Assembly Technologies

The manufacturing sector in India is currently undergoing a massive technological overhaul driven by the urgent need to increase production capacities and reduce operational costs. This industrial shift has placed the spotlight firmly on the capabilities of every innovative Automatic Assembly Machine Manufacturer. These engineering firms are revolutionizing how products are put together by replacing manual labor with sophisticated robotic systems and high speed automated stations. The transition from manual to automatic assembly is not just about speed it is about achieving a level of consistency that human hands cannot match. In industries like automotive and electronics where precision is critical even a microscopic error can lead to product failure. Therefore manufacturers are leveraging advanced sensors and vision systems to ensure that every screw is tightened to the exact torque and every component is placed with absolute accuracy. This commitment to precision engineering by the Assembly Equipment Machines Manufacturer in India is enabling domestic companies to meet global quality standards and compete effectively in international markets.

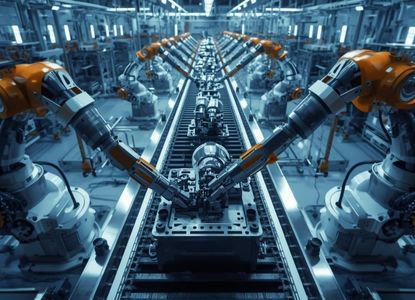

At the heart of a modern factory lies the integrated system designed by an expert Assembly Line Equipment Manufacturer. These professionals do not just build standalone machines they engineer the entire flow of the production floor. They design intelligent conveyor systems and transfer units that move parts seamlessly from one station to the next reducing idle time and maximizing throughput. The synchronization of these systems is vital for maintaining a continuous production rhythm. By implementing a well designed assembly line factories can significantly reduce their work in progress inventory and optimize their floor space utilization. Furthermore these automated lines are equipped with data collection capabilities that allow factory managers to monitor production metrics in real time. This data driven approach enables quick identification of bottlenecks and facilitates continuous process improvement. The ability to track and trace every product on the line enhances accountability and ensures that quality control is maintained at every step of the manufacturing process.

However the successful implementation of automation requires more than just buying machinery it requires a strong partnership with a reliable Assembly Equipment Machines Supplier in India. A competent supplier plays a crucial role in the installation and commissioning of these complex systems. They provide the necessary technical training to the workforce ensuring that operators are comfortable handling the new technology. Moreover the supplier is the first line of defense when technical issues arise providing prompt maintenance services to prevent costly downtime. As industries continue to evolve the collaboration between the manufacturer the system integrator and the supplier becomes increasingly important. By choosing the right partners businesses can ensure a smooth transition to automation unlocking new levels of productivity and profitability. This strategic investment in advanced assembly technology is the key to building a resilient manufacturing infrastructure that is ready for the challenges of the future.