Emerging Trends In Hardware Material Manufacturing Across Industries

Hardware material manufacturing is undergoing a quiet revolution as industries demand stronger, lighter, smarter, and more sustainable components. In India, manufacturers are upgrading from traditional workshop models to technology-driven, globally competitive operations. The change is visible in automated production lines, advanced testing facilities, eco-friendly coatings, and increasingly, data-guided decision-making. These shifts go far beyond simple cost reduction; they reshape how quickly new products are developed, how consistent quality becomes, and how responsibly resources are used. For architects, builders, OEMs, and infrastructure developers, understanding these trends is crucial. It helps you choose partners who are prepared for the future, capable of meeting rising expectations on performance, appearance, sustainability, and digital integration across the full life cycle of hardware products.

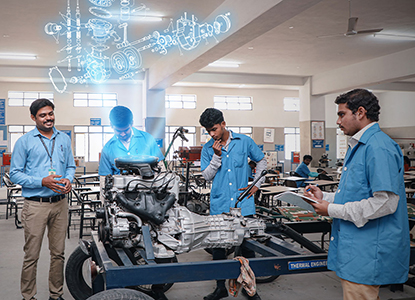

How Is Automation Changing Hardware Material Manufacturing Today?

Automation has moved from being a distant aspiration to an everyday reality in forward-looking hardware factories. CNC machines, robotic arms, and automated feeding systems now handle cutting, drilling, forming, and finishing operations with high repeatability. This reduces human error and ensures tight tolerances across large batches, which is essential for engineered hardware components. Automated inspection systems using cameras or sensors can check dimensions and surface defects much faster than manual methods. Additionally, integrated production planning software coordinates machine schedules, material flow, and maintenance, improving utilisation and reducing downtime. For customers, these advances translate into more consistent product quality, shorter lead times, and better scalability when project demands suddenly rise. Automation, when combined with skilled supervision, becomes a powerful driver of reliability.

What New Materials Are Shaping Modern Hardware Design?

Modern hardware design increasingly relies on innovative materials that balance strength, weight, and aesthetics. High-performance stainless steel grades offer improved corrosion resistance for coastal or industrial environments, while advanced aluminium alloys provide strength with reduced weight, ideal for large doors, façades, or transport applications. Engineers are also exploring micro-alloyed steels and special coatings that deliver better fatigue performance or lower friction. Composite materials and engineered plastics sometimes replace traditional metals in low-load or decorative components, offering design freedom in shape and colour. These material innovations allow hardware to meet stricter performance criteria while retaining a sleek, modern appearance. Collaboration between manufacturers, material scientists, and designers is driving this evolution toward smarter, more efficient hardware solutions.

How Are Manufacturers Improving Sustainability And Recycling Efforts?

Sustainability is moving from a marketing slogan to a core operational principle. Many hardware manufacturers now track and reduce energy consumption through efficient motors, optimised furnace cycles, and heat recovery systems. They invest in water treatment and recycling, especially where surface finishing processes generate effluents. Powder coating and advanced plating technologies help cut hazardous emissions and waste. Scrap metal is systematically collected and routed back into the recycling stream, reducing raw material demand. Some manufacturers also design products for easier disassembly and recycling at end-of-life, aligning with circular economy principles. Customers benefit not only from a smaller environmental footprint but also often from improved process control and longevity that accompany these sustainability initiatives.

Why Is Customisation Becoming Standard In Hardware Production?

Customisation used to be restricted to special projects; today it is rapidly becoming an expectation. Clients want hardware that fits unique architectural concepts, brand identities, or engineering constraints. With digital design tools and flexible manufacturing technologies, manufacturers can now handle smaller batches of customised parts economically. They can adjust dimensions, hole patterns, load ratings, surface finishes, and even colours without redesigning entire systems from scratch. 3D CAD and simulation software allow rapid virtual testing before any metal is cut. This agility helps architects and engineers experiment with bolder designs while staying within safety and performance envelopes. As more sectors emphasise differentiation and user experience, customisable hardware is set to become a competitive necessity.

How Do Digital Tools Enhance Quality Control Processes?

Digital tools are transforming quality control from sporadic inspection into continuous monitoring. Manufacturers increasingly use digital measuring equipment that uploads data directly into quality management systems, enabling real-time analysis of trends and anomalies. Barcode- or RFID-based traceability links each batch to specific machines, operators, and raw materials, so root causes of issues can be identified and addressed swiftly. Statistical process control (SPC) charts help maintain processes within tight tolerance bands, reducing rejections and rework. Some factories deploy vision systems that inspect every piece on high-speed lines, flagging defects instantly. For customers, digital quality control means greater transparency, easier audits, and more confidence that hardware will meet or exceed the promised performance standards consistently.

What Future Innovations Could Transform Hardware Materials Next?

Looking ahead, several innovations are poised to reshape hardware manufacturing even more dramatically. Additive manufacturing (3D printing) of metals may enable highly complex, lightweight geometries that traditional machining cannot easily produce, especially for low-volume, high-value components. Smart hardware, embedded with sensors, could monitor load, vibration, or tampering, feeding data into building management or industrial monitoring systems. New surface technologies, such as self-healing coatings or ultra-hydrophobic finishes, could extend durability further while simplifying cleaning and maintenance. Materials research may yield alloys that combine even higher strength with improved corrosion and fatigue resistance. As these technologies mature, manufacturers who invest early will offer customers not just parts, but intelligent, data-rich, long-lasting hardware ecosystems.

Conclusion

The landscape of hardware material manufacturing is shifting rapidly under the influence of automation, advanced materials, sustainability, customisation, and digital quality control. For buyers and specifiers, understanding these trends is more than an academic exercise; it is the key to selecting partners who will remain capable and competitive over the life of your projects. Manufacturers embracing innovation can deliver better performance, cleaner processes, and more flexible, design-friendly products. Those who lag behind risk becoming sources of hidden risk and unreliability. By aligning yourself with forward-thinking hardware producers, you prepare your projects for the future benefiting from stronger, smarter, more sustainable components that keep your buildings, machines, and infrastructures performing at their best for years to come.