Engineering Excellence in Heavy Duty Laundry Operations

The industrial laundry sector in India is experiencing a paradigm shift as businesses increasingly demand higher efficiency and durability from their cleaning equipment. This demand places a significant responsibility on every proficient Industrial Washing Machine Manufacturer in India. These engineering firms are tasked with designing machines that can withstand the relentless pressure of processing tons of linen daily. Unlike domestic appliances which are built for intermittent use industrial machines must operate continuously often for twenty hours a day in environments like hospitals hotels and large textile factories. To meet these rigorous standards manufacturers are utilizing high grade stainless steel and reinforced frames to prevent corrosion and structural vibration. The focus is on creating a robust chassis that ensures stability during high speed extraction cycles. Furthermore an Industrial Laundry Equipment Manufacturer today is deeply invested in research and development to integrate smart technology into these heavy metal giants. Features such as programmable logic controllers allow operators to customize wash cycles for specific fabric types ensuring that delicate linens are treated with care while heavily soiled uniforms receive the aggressive cleaning they require. This balance of brute strength and digital intelligence is what defines the modern industrial washing machine.

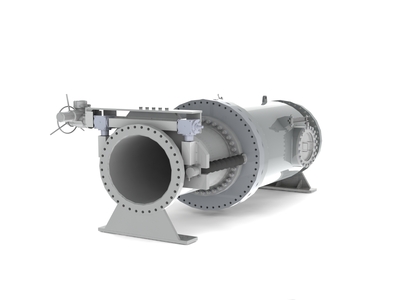

In the realm of large scale fabric processing the role of a specialized Heavy Duty Washing Machine Manufacturer India is pivotal. These manufacturers focus on the upper end of the capacity spectrum producing washer extractors that can handle loads ranging from fifty kilograms to over two hundred kilograms in a single cycle. The engineering challenges here are immense as the machine must manage massive water volumes and dynamic forces without failing. These heavy duty units are equipped with powerful motors and advanced suspension systems that absorb shock effectively eliminating the need for expensive special foundations. Additionally energy efficiency has become a core design philosophy. Modern machines are designed to consume less water and energy per kilogram of linen washed which significantly lowers operational costs for the facility owner. By optimizing the water to cloth ratio and using precise chemical dosing systems these manufacturers help businesses achieve superior cleaning results while minimizing their environmental footprint. This commitment to sustainable engineering is crucial as the industry faces stricter environmental regulations and rising utility costs.

Ultimately the relationship between a facility and its machinery provider is one of long term trust. When a business partners with a reputable Industrial Washing Machine Supplier in India they are looking for more than just a vendor they seek a solution provider. The manufacturer must ensure that the machine is not only built to last but is also easy to maintain. Accessibility to key components like drain valves and heating elements is designed into the machine layout to facilitate quick service checks. This user centric design approach reduces downtime and ensures that the laundry operations remain uninterrupted. As the Indian market continues to mature the distinction between a generic assembler and a true engineering manufacturer becomes clear. The latter offers comprehensive documentation operator training and a guarantee of performance that protects the investment of the client. By choosing a manufacturer with a proven track record of engineering excellence businesses can secure a laundry infrastructure that is resilient efficient and capable of supporting their growth for decades to come.