Exploring Key Uses of Plastic Products Across Major Industries in India

Introduction:

Plastics have become an essential building block of modern life, and nowhere is this more visible than in the diverse applications of plastic products across industries in India. From farms and construction sites to hospitals, supermarkets, and homes, well-designed plastic components deliver efficiency, safety, and affordability. Advances in material science, molding technology, and design have allowed manufacturers to tailor products precisely for each sectors unique demands. This means better durability in harsh conditions, improved hygiene in sensitive environments, and smarter logistics for moving goods nationwide. In this blog, we explore how plastic products are driving growth and innovation across key Indian industries, illustrating why choosing the right manufacturer and material is so important.

How are plastic products transforming agriculture in India?

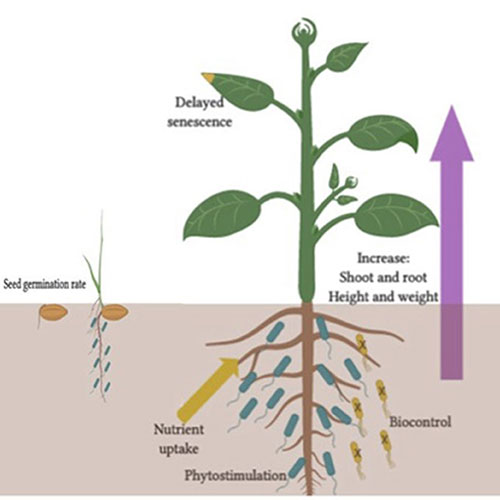

Modern plastic products for agriculture in India help farmers increase yields, conserve water, and protect crops from unpredictable weather. Drip irrigation systems use plastic pipes, emitters, and connectors to deliver water directly to plant roots, reducing wastage and energy costs. Mulch films cover soil to retain moisture, control weeds, and maintain temperature for better germination. Greenhouse structures made with plastic films extend growing seasons and allow cultivation of high-value crops. Crates and bins simplify harvesting and transport of fruits and vegetables, reducing spoilage. Durable yet lightweight materials make these products easy to install, relocate, and maintain, enabling even small farmers to adopt modern techniques and improve their incomes sustainably.

Why are plastics vital for the construction and infrastructure sector?

The demand for plastic solutions for construction in India has grown as builders seek materials that are strong, lightweight, and resistant to corrosion. Plastic pipes and fittings carry water, sewage, and electrical conduits safely through buildings and infrastructure projects, outlasting many traditional materials in harsh conditions. Insulation materials improve energy efficiency, while plastic formwork systems can be reused multiple times, cutting costs and waste. Profiles and panels made from engineered plastics offer weather resistance and low maintenance for doors, windows, and facades. On-site safety is enhanced by brightly colored barriers, helmets, and signage made from tough polymers. Together, these applications help construction companies deliver faster, safer, and more durable projects.

How do plastics support the fast-growing electronics industry?

The electronics sector relies heavily on plastic components for electronics in India because plastics provide electrical insulation, precise tolerances, and design flexibility. Housings for mobile phones, routers, televisions, and home appliances must withstand heat, impact, and daily handling while maintaining attractive aesthetics. Connectors, switches, and PCB supports use specialized engineering plastics with controlled flame-retardant properties. Accurate molding ensures tight fits and reliable performance, which is critical for sensitive electronic circuits. Additionally, antistatic trays and packaging protect delicate components during assembly and transport. By leveraging tailored materials and precision molding, plastic manufacturers help electronics companies bring sleek, reliable, and affordable devices to consumers across India.

What makes plastic indispensable in FMCG packaging?

FMCG brands depend on plastic packaging for FMCG in India to protect products, extend shelf life, and communicate brand identity. Lightweight bottles, jars, pouches, and caps keep food, beverages, and personal care items safe from contamination and damage. Barrier properties of certain plastics maintain freshness by limiting exposure to moisture and oxygen. Transparent containers allow shoppers to see contents, while colourful designs and custom shapes catch attention on retail shelves. Tamper-evident closures enhance consumer trust. At the same time, brands are increasingly exploring recyclable and mono-material solutions to reduce environmental impact. With the right combination of design and material, plastic packaging delivers both performance and sustainability for FMCG companies.

How do plastic logistics products improve supply chains?

Efficient movement of goods depends on robust plastic crates and pallets in India, which have largely replaced traditional wooden alternatives in many sectors. Plastic pallets are lighter, uniform, and resistant to moisture, insects, and splinters, making them ideal for hygienic environments like food processing and pharmaceuticals. Crates offer stackability, ventilation, and impact resistance, protecting produce and packaged goods during transport. Their long service life reduces total cost over time, while standardized sizes improve warehouse and truck space utilisation. Because they can be easily washed and sanitized, plastic logistics products support better hygiene and compliance with modern quality standards throughout the supply chain.

How critical are plastics in healthcare and medical applications?

The healthcare sector relies extensively on medical grade plastic devices in India for safety, accuracy, and hygiene. Syringes, IV components, diagnostic test kits, and many disposable instruments are made from carefully selected medical polymers that meet strict biocompatibility and sterilization requirements. Lightweight, transparent, and shatter-resistant plastics improve user safety and comfort for patients and medical staff alike. In hospitals and clinics, plastic trays, containers, and trolleys aid infection control because they can be cleaned thoroughly and replaced easily. Specialized manufacturers adhere to rigorous quality systems, traceability, and regulatory compliance, ensuring that every product performs reliably when lives are at stake.

How are plastics used in water management and household infrastructure?

Access to safe water and sanitation is enhanced by plastic water storage tanks in India and extensive networks of plastic pipes and fittings in India. Tanks made from UV-stabilized polymers can withstand outdoor exposure for years, while their lightweight nature allows for easy installation even on rooftops. Plastic plumbing systems resist corrosion and internal scaling, maintaining flow and water quality over time. In addition, household items like buckets, dustbins, furniture, and kitchenware provide affordable, long lasting solutions for everyday needs. Because plastics can be moulded into virtually any shape, they enable space-saving designs and ergonomic features that improve comfort and convenience in Indian homes.

Conclusion:

From agriculture and construction to FMCG, electronics, logistics, and healthcare, the impact of well-designed plastic products across industries in India is both deep and far-reaching. These materials and components make essential services more accessible, efficient, and affordable for businesses and consumers alike. The key to harnessing their full potential lies in working with knowledgeable manufacturers who understand application requirements, material behavior, and regulatory constraints. With ongoing advances in design, processing, and sustainability, plastics will continue to play a central role in Indias growth story. By choosing the right products and partners, companies can unlock new efficiencies and innovations while moving toward a more sustainable future.