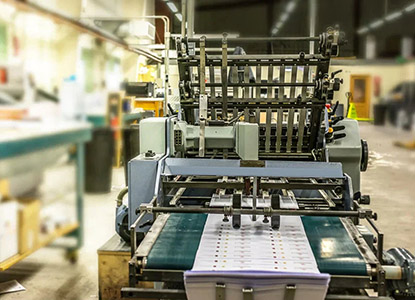

How Creasing Machines Improve Efficiency in Printing and Packaging

Creasing machines are essential in modern printing and packaging operations. They streamline production, reduce errors, and enhance the quality of printed materials, ensuring faster turnaround and cost-effective results.

- Faster Production: Creasing machines automate the folding process, significantly reducing manual labor and speeding up printing and packaging workflows for large-scale operations.

- Consistent Crease Quality: Automated machines create uniform and precise creases, ensuring professional-quality packaging, brochures, and printed materials every time.

- Minimizes Material Waste: Accurate creasing reduces misaligned folds and errors, lowering paper, cardboard, and packaging material wastage during production.

- Handles High Volumes: Modern creasing machines are built for continuous operation, efficiently processing large batches without compromising on accuracy or quality.

- Reduces Manual Labor: By automating repetitive tasks, these machines reduce the need for intensive manual work, freeing staff for other production activities.

- Supports Complex Designs: Advanced creasing machines can handle intricate fold patterns, customized packaging shapes, and specialty materials with precision.

- Enhances Overall Workflow Efficiency: By integrating creasing into the production line, businesses achieve faster turnaround, reduced errors, and cost savings, improving overall operational efficiency.