Navigating the Supply Chain and Pricing for Industrial Rope Machinery

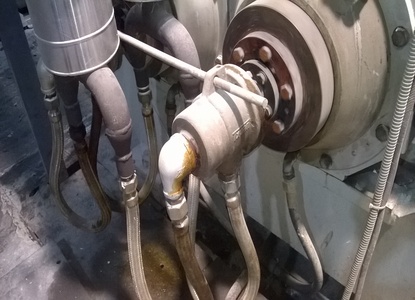

For large scale industrial operations the sourcing of heavy duty machinery is a critical strategic decision that impacts long term profitability. An Industrial Rope Making Machine Manufacturer specializes in building massive systems capable of producing thick towing ropes, mooring lines, and heavy lifting slings. These machines must withstand immense physical stress and operate continuously for days. Therefore the procurement process involves a careful evaluation of build quality, motor capacity, and safety features. However directly accessing the manufacturer is not always feasible or efficient for every buyer which is where the Rope Manufacturing Machine Dealer in India becomes essential. Dealers serve as the local face of the manufacturer providing a convenient touchpoint for inspection, negotiation, and purchase. They often stock standard models and fast moving spare parts ensuring that industrial clients have immediate access to essential resources. A reliable dealer adds value by offering localized service support and bridging the communication gap between the factory and the end user ensuring that specific customization requests are clearly understood and executed.

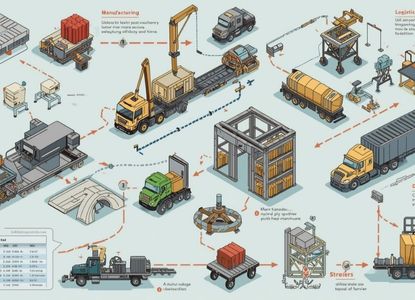

To ensure that advanced rope making technology reaches every industrial cluster across the vast geography of the country the network of the Rope Making Machine Distributor India plays a vital role. Distributors manage the complex logistics of transporting heavy machinery across state lines handling the necessary documentation and insurance. They ensure that even factories located in remote coastal areas or interior agricultural belts have access to the same high quality technology as those in major metropolitan hubs. Distributors often have the financial capacity to hold inventory which reduces the delivery lead time for urgent orders. They also serve as a feedback channel relaying market trends and customer requirements back to the manufacturers which helps in the continuous improvement of machine designs. By maintaining a robust distribution network the industry ensures a seamless flow of technology that keeps the Indian rope manufacturing sector competitive and agile.

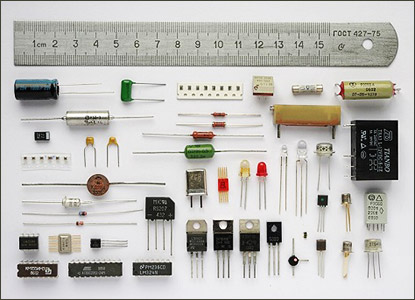

Ultimately the investment decision often hinges on the Rope Making Machine Price in India. The cost of machinery varies widely depending on factors such as production capacity, automation level, and the origin of key components like gears and motors. While price is a significant factor experienced industrialists advise against making it the sole criterion. A cheaper machine may have a lower initial cost but could incur higher maintenance expenses and suffer from frequent breakdowns leading to production losses. It is crucial to evaluate the total cost of ownership which includes energy consumption, spare parts availability, and the expected lifespan of the machine. A transparent pricing structure from a reputable supplier helps buyers make informed decisions. By balancing cost considerations with quality assurance and after sales support business owners can secure machinery that delivers a high return on investment and drives sustainable growth for their rope manufacturing enterprise.