Optimizing Industrial Infrastructure with Reliable Supply Chains

The successful construction and maintenance of industrial facilities depend heavily on a robust and responsive supply chain for piping materials. A professional Piping System Supplier in India acts as the linchpin in this ecosystem connecting the engineering requirements of the project with the manufacturing capabilities of the industry. These suppliers are not merely traders they are technical procurement specialists who understand the intricate specifications of industrial piping. They assist project managers in sourcing materials that meet the exact grade, size, and standard required for the application. Whether it is sourcing large diameter pipes for a water transmission line or specialized high pressure fittings for a gas pipeline the supplier leverages their extensive network to find the right products at the right time. They also play a crucial role in documentation ensuring that every pipe supplied is accompanied by mill test certificates and third party inspection reports. This level of traceability is essential for quality assurance and compliance with regulatory norms. By acting as a central resource for all piping needs the supplier simplifies the procurement process and allows the project team to focus on construction and commissioning activities.

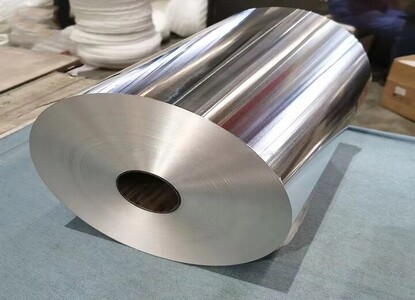

For ongoing maintenance and smaller scale requirements the extensive network of the Piping System Dealer in India provides a critical layer of support. Dealers are strategically located in industrial clusters to provide immediate off the shelf availability of standard piping components. When a plant faces a sudden breakdown due to a leaking pipe or a failed valve waiting for a factory shipment is not an option. A local dealer can supply the necessary replacement parts within hours minimizing production downtime and preventing revenue loss. Dealers typically maintain a diverse inventory of carbon steel and stainless steel pipes along with common fittings like elbows, tees, and reducers. They also provide essential consumables such as gaskets, bolts, and welding rods making them a one stop shop for routine maintenance teams. The personalized service provided by dealers including cutting pipes to specific lengths and arranging local transport adds significant value for small and medium enterprises. This local accessibility ensures that industries can maintain their operational continuity without carrying excessive inventory on their own books.

On a national scale the Piping System Distributor India network ensures that advanced piping technology reaches even the most remote infrastructure projects. Distributors bridge the logistical gap between large manufacturing hubs and regional construction sites. They manage the complex logistics of transporting heavy and bulky piping materials across state lines handling challenges related to warehousing, insurance, and taxation. Distributors often have the financial capacity to hold bulk stock which allows them to buffer against market price fluctuations and supply shortages. This stability is vital for large infrastructure projects that span multiple years. Furthermore distributors act as a channel for knowledge transfer introducing new products and technologies from global manufacturers to the local market. They organize technical seminars and product demonstrations to educate engineers and contractors about the benefits of using advanced materials like composite pipes or coated steel pipes. By ensuring a steady flow of materials and information the distributor network supports the balanced development of industrial infrastructure across the entire nation.