Revolutionizing Warehouse Efficiency with Advanced Plastic Storage Systems

Introduction

In the fast-paced world of Indian manufacturing and heavy industry, organisation is not just a luxury; it is a necessity. The efficiency of a production line or a warehouse often hinges on how materials are stored, accessed, and transported. This is where the role of high-quality storage containers becomes critical. Industrial environments are harsh; they involve heavy loads, exposure to chemicals, and rough handling. Therefore, standard storage solutions often fail. This blog explores the vital importance of choosing the right industrial storage partners and how specific container types can transform operational efficiency. We will delve into the technical aspects of durability, the versatility of design, and the economic benefits of investing in premium storage solutions specifically tailored for the Indian market. From automotive giants to small-scale workshops, the need for robust industrial tote box manufacturers in India is universal. Let us navigate through the essential questions that every facility manager asks when upgrading their storage infrastructure.

How do heavy-duty crates improve safety in manufacturing plants?

Safety in a manufacturing environment is paramount, and it often starts with how materials are handled. Using heavy-duty plastic crates suppliers in India ensures that the containers used on the shop floor are structurally sound. Unlike cardboard or inferior plastic, heavy-duty crates do not buckle under weight. When workers are carrying or stacking heavy automotive parts or metal components, a container failure can lead to serious injuries. These crates are designed with reinforced corners and ribbed walls to handle significant vertical loads. Furthermore, they provide a stable grip, reducing the likelihood of slips and drops. By using standardized, high-strength containers, aisles remain clear of debris from broken boxes, and stacks remain stable, preventing dangerous topples. This proactive approach to safety not only protects the workforce but also prevents damage to expensive machinery and automotive parts storage bins in India, ensuring a smooth and accident-free production cycle.

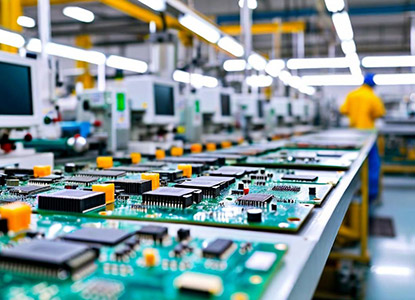

Why are conductive bins essential for the electronics industry?

The electronics manufacturing sector in India is booming, and with it comes the specific challenge of Electrostatic Discharge (ESD). Standard plastic generates static electricity, which can instantly destroy sensitive electronic components like circuit boards and microchips. This is why conductive ESD bins in India are non-negotiable for this sector. These specialized containers are made from carbon-conductive copolymer polypropylene, which safely dissipates static charges, protecting the contents. It is not just about storage; it is about shielding the product during every step of the assembly and transport process. Investing in these bins prevents latent damage defects that might not show up immediately but cause the product to fail later in the hands of the consumer. For any electronics assembly unit, these bins are an insurance policy against high rejection rates. They ensure that the delicate components remain static-free, thereby maintaining the high-quality standards required in the competitive electronics market.

What are the benefits of using stack and nest containers for logistics?

Space optimisation is the holy grail of logistics and warehousing. Stack and nest containers in India offer a dual advantage that directly impacts the bottom line. When these containers are full, they stack securely on top of one another, often without the need for lids, thanks to their clever design. This allows for maximum utilisation of truck space and warehouse vertical racking. However, the real magic happens during the return journey. When empty, these containers nest inside each other, reducing their volume by up to 70%. This significant reduction means that a truck returning to the warehouse can carry three to four times as many empty containers as full ones. For logistics companies operating on tight margins, this efficiency in reverse logistics translates to massive fuel savings and reduced carbon footprint. It makes the supply chain leaner and more cost-effective.

How can warehouse shelving bins maximize small parts storage?

In many industries, the challenge is not storing large items but managing thousands of tiny components like screws, nuts, bolts, and washers. Warehouse shelving bins in India are the answer to this chaotic inventory. These open-front bins are designed to sit on shelves or hang on louvre panels, providing easy visibility and quick access to small parts. By utilising colour-coded bins, warehouse managers can categorise inventory by type, size, or usage frequency. This visual organisation significantly speeds up the picking process, as workers spend less time searching for parts and more time fulfilling orders. Furthermore, these bins utilize the depth of the shelves effectively, ensuring no space is wasted. For e-commerce fulfilment centres or spare parts divisions, these bins are essential for maintaining accuracy and speed in order processing.

Are plastic pallet boxes a better alternative to wooden crates?

For decades, wood was the standard for bulk storage, but plastic pallet boxes in India are rapidly replacing them for good reasons. Wood is susceptible to moisture, rot, and pests, and it often requires fumigation for export. Plastic pallet boxes, on the other hand, are hygienic, easy to clean, and impervious to water and chemicals. They are moulded as a single unit or with collapsable sides, offering incredible strength for large-volume storage containers in India. They do not have nails or splinters that can damage goods or injure workers. Additionally, plastic pallet boxes have a much longer lifespan than wood. While the initial investment might be higher, the durability and lack of maintenance costs make them cheaper in the long run. They are consistent in weight, which is crucial for air freight, and they look professional, enhancing the brand image when delivering goods to clients.

Conclusion

To conclude, the landscape of industrial storage in India is evolving towards more specialized, durable, and efficient solutions. Whether it is protecting sensitive electronics with conductive ESD bins in India or moving bulk goods with plastic pallet boxes in India, the choice of container dictates the efficiency of the operation. Businesses that invest in high-quality manufacturing material handling in India products position themselves for better productivity, higher safety standards, and lower long-term operational costs. As the Indian industrial sector continues to expand globally, partnering with reliable suppliers who understand these nuances is key to staying competitive.