The Rise of Collaborative Automation in Indian Manufacturing

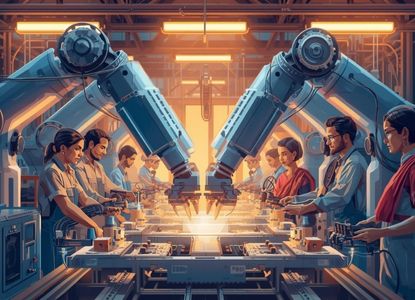

The manufacturing sector in India is experiencing a significant transformation as industries increasingly adopt collaborative automation to enhance productivity and safety. This shift is characterized by the integration of cobots which are designed to work alongside human operators without the need for restrictive safety cages. A forward thinking Collaborative Assembly Robots Manufacturer is at the forefront of this change engineering versatile robots that can perform delicate tasks such as screw driving and component insertion with high precision. Unlike traditional industrial robots that require extensive programming and dedicated floor space cobots offer flexibility and ease of deployment. They are equipped with advanced sensors that detect the presence of humans ensuring safe operation in shared workspaces. This technology is particularly beneficial for small and medium enterprises in India where floor space is often limited and the need for adaptable production lines is high. By leveraging the expertise of a reliable Assembly Robots Supplier in India businesses can access these advanced tools to bridge the gap between manual labor and full automation.

The adoption of collaborative robots is also driven by the need to improve ergonomic conditions for workers. Repetitive strain injuries are a common concern in assembly lines where operators perform the same motion thousands of times a day. A proficient Robotic Assembly System Manufacturer India addresses this issue by designing work cells where cobots handle the physically demanding and monotonous tasks while humans focus on quality control and complex decision making. This symbiotic relationship not only boosts morale but also significantly reduces the error rate in production. Furthermore the intuitive programming interfaces of modern cobots allow shop floor staff to retrain the robot for new tasks quickly. This adaptability is crucial for industries with high product mix and low volume requirements such as the electronics and consumer goods sectors. As a result manufacturers can respond faster to market changes without incurring the high costs associated with reconfiguring traditional automation systems.

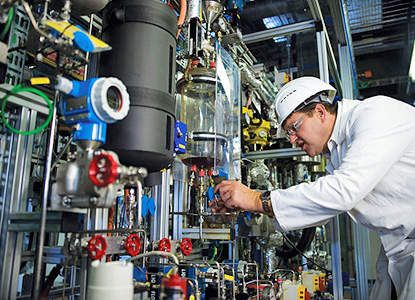

Partnering with a leading Assembly Robots Manufacturer in India ensures that businesses receive support tailored to local operational challenges. These manufacturers understand the specific needs of the Indian market including voltage fluctuations and dust protection requirements. They build robust systems that can withstand harsh industrial environments while delivering consistent performance. Moreover the availability of local technical support and spare parts is a critical factor in minimizing downtime. By choosing a manufacturer with a strong domestic presence companies can ensure seamless integration and long term reliability of their robotic assets. This strategic investment in collaborative technology not only enhances operational efficiency but also positions Indian manufacturers as competitive players in the global supply chain capable of delivering high quality products with speed and precision.