The Strategic Advantage of Automating Vacuum Processes in Industry

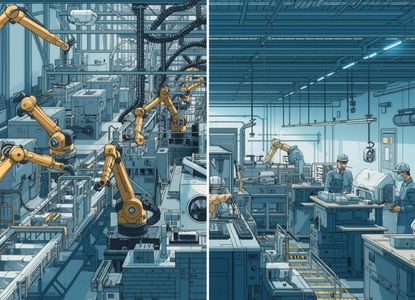

In the current competitive industrial landscape the drive for higher productivity and consistent quality is relentless. This pressure has made the reliance on manual vacuum processes increasingly untenable for large scale operations. The transition towards automation is led by the expertise of the forward thinking Automatic Vacuum Machinery Manufacturer. These engineering firms are redefining production lines by integrating sophisticated control systems and robotics into vacuum technology. By automating tasks such as air extraction sealing and material transfer factories can achieve a level of speed and precision that human labor simply cannot match. This is particularly evident in sectors dependent on a Vacuum Packaging Machine Manufacturer India where consistent seal integrity is crucial for product safety and shelf life. Automation ensures that every cycle is identical reducing the risk of human error and minimizing product wastage. The shift to automated systems is not merely about replacing workers it is about upskilling the workforce to manage advanced technology while the machines handle the repetitive and physically demanding tasks thereby improving overall plant safety and efficiency.

The technological advancements incorporated by a leading Industrial Vacuum Machine Manufacturer go beyond simple mechanical automation. Modern automatic vacuum systems are equipped with intelligent sensors and programmable logic controllers that provide real time data on process parameters like pressure levels cycle times and temperature. This data driven approach allows production managers to monitor performance continuously and identify potential bottlenecks before they escalate into major issues. For instance in vacuum drying or degassing applications automatic systems can adjust the pressure cycle dynamically based on the moisture content of the material ensuring optimal results every time without manual intervention. Furthermore these advanced machines often feature self diagnostic capabilities which simplify maintenance schedules and reduce unexpected downtime. The integration of such smart technology turns the vacuum machinery from a passive tool into an active participant in the manufacturing process contributing to smarter decision making and continuous operational improvement.

While the initial investment required for fully automated vacuum solutions is higher compared to manual or semi automatic options the long term return on investment is substantial. Smart business leaders recognize that true cost efficiency is measured over the entire lifecycle of the equipment. Automated machines from a premier Vacuum Based Machinery Manufacturer in India deliver value through increased daily throughput lower operational costs and reduced material scrap rates. Moreover the ability to meet large orders with tight deadlines reliably enhances client satisfaction and strengthens market position. In an era where speed and quality define success embracing automation in vacuum processes is no longer optional it is a strategic necessity for any industrial entity aiming for sustainable growth and global competitiveness.