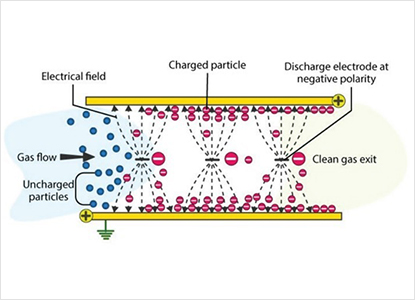

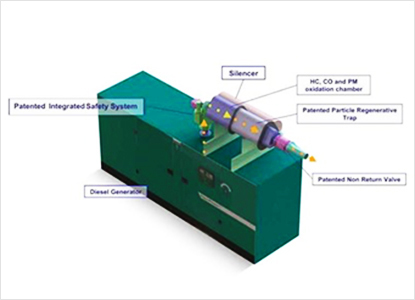

Retrofit Emission Control Devices for Diesel Gensets (RECD) is a critical technical and regulatory process that ensures your Commercial Diesel Generators meet stringent pollution norms. The journey begins with a meticulous Site Inspection by a certified RECD Kit Installation Company Near Me. This initial phase is crucial and involves a technical team assessing your specific DG set capacity (kVA), engine model, existing exhaust system configuration, and the available space for the new device. Based on this assessment, the expert determines the most suitable, CPCB Approved RECD Kit for DG Sets technology—whether it is a Diesel Particulate Filter (DPF), a Diesel Oxidation Catalyst (DOC), or a filterless system like Electrostatic Precipitators (ESP)—that guarantees the minimum 70% PM reduction as required by the DG Set Retrofit Kit as per CPCB Norms. Choosing the right product ensures maximum efficiency and minimal impact on the engine performance, preventing issues like excessive backpressure that could damage your DG set.

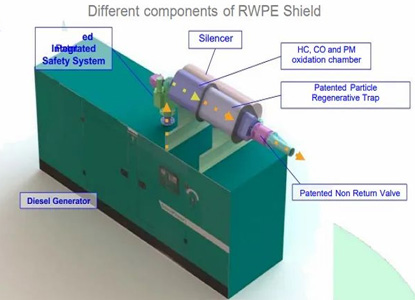

RECD Kit for DG Sets Fitting and Installation solution once selected, the physical retrofitting process takes place, which is generally designed to be non-invasive. The core step involves replacing or integrating the RECD unit into the existing exhaust line, typically where the silencer or muffler is located. Highly trained technicians from Authorized RECD Installation Centers in Delhi meticulously handle the installation, which involves:

1) Exhaust System Modification: Carefully disconnecting a section of the existing exhaust piping to accommodate the RECD module.

2) Secure Mounting: Physically securing the RECD unit, which can be heavy, using robust mounting brackets and supports to ensure it withstands the DG set vibrations and heat.

3) Connecting Sensors and Controls: Wiring the necessary sensors (e.g., temperature, pressure) and the monitoring unit/display, which track the RECD performance and aid in compliance reporting. The installation team ensures all connections are sealed to prevent exhaust gas leakage and that the system wiring is protected from the high temperatures of the exhaust. For large Industrial DG Sets, this step may also involve custom fabrication of structural supports or ducting to integrate the Diesel Generator Emission Control System seamlessly.

Testing and Compliance Validation for RECD, which completes the Retrofit Emission Control Device Installation Services. After the physical installation of the Diesel Genset Pollution Control Kits is finished, the DG set is run under a representative load condition. Post-Installation Testing is conducted using CPCB-mandated equipment to verify that the system successfully meets the prescribed emission reduction targets. This test generates the essential performance report that confirms the Low Emission Diesel Genset Retrofit Solutions are working as intended. A reliable RECD Kit Manufacturer and Supplier in Delhi will then provide you with all necessary documentation, including the product warranty, the installation certificate, and the emission compliance report, for submission to the concerned pollution control board. This systematic approach ensures that your generator is fully compliant, providing peace of mind and allowing you to focus on your core operations without the fear of penalties or shutdowns.