Automated Diverter Control allows precise routing, remote monitoring, and programmable settings, ensuring every bag or bulk product reaches the correct destination without human error. Enhancing Diverter Seal Efficiency reduces leaks, dust emission, and product contamination, which is crucial for food, pharmaceutical, or chemical processing industries. A Modular Diverter Design provides flexibility, making it easier to scale production lines, swap components, or adapt layouts without expensive downtime. Dust Tight Construction protects the facility and workers by containing particles, ensuring compliance with safety standards and improving overall cleanliness. With a Quick Changeover Mechanism, operators can transition between products or bag sizes rapidly, minimizing production interruptions and increasing line efficiency. Together, these features create reliable, safe, and efficient material handling solutions that improve throughput, reduce operational costs, and maximize ROI. By integrating these technologies, facilities can achieve long-term performance gains, operational flexibility, and a measurable competitive advantage in industrial production.

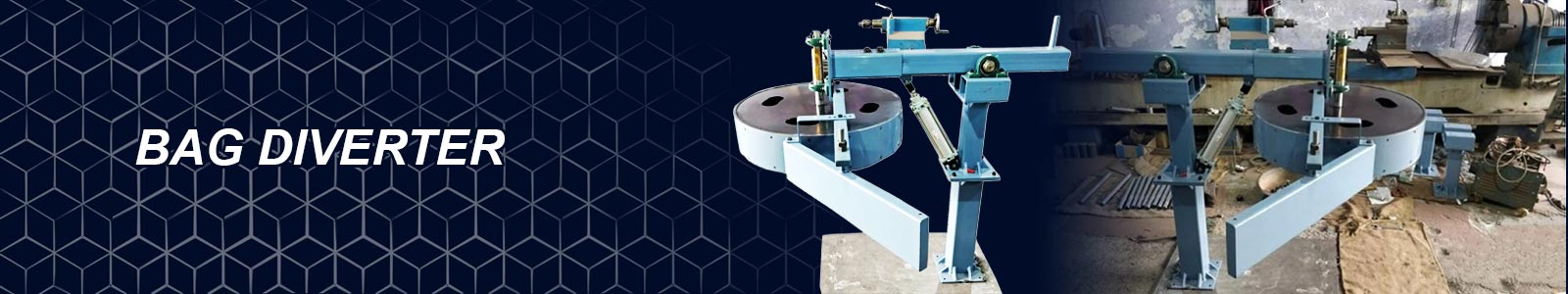

Bag Diverter integrated with a Modular Diverter Design creates scalable and adaptable solutions for warehouses, packaging lines, and manufacturing facilities, allowing lines to expand or reconfigure without downtime. Optimized Conveyor System Integration ensures seamless movement of materials across multiple stages of production, preventing bottlenecks and increasing overall efficiency. Using a Rotary Airlock Diverter guarantees consistent product flow while protecting sensitive materials from contamination, abrasion, or spillage. Implementing Automated Diverter Control provides precise operation, real-time monitoring, and programmable routing, reducing human error and operational delays. Together, these solutions enhance line throughput, minimize labor requirements, and improve safety across production environments. Companies benefit from reduced downtime, higher productivity, and improved operational flexibility. This combination of advanced diverter technologies ensures that facilities maintain reliable, high-performance material handling systems, supporting both short-term efficiency gains and long-term business growth while maximizing return on investment in automation and equipment upgrades.