CNG Cylinder Hydro Testing Services are essential for maintaining the safety and integrity of vehicles running on compressed natural gas. This process involves a rigorous examination of the cylinder to ensure it can withstand high pressure without leaking or bursting. Every vehicle owner must understand that a CNG cylinder endures immense stress during daily refilling cycles. Over time the metal expands and contracts which can lead to fatigue or structural weaknesses that are not visible to the naked eye. To detect these potential hazards experts perform a CNG Tank Hydrostatic Test where the cylinder is filled with water and pressurized to a level significantly higher than its normal operating limit. This method determines if the cylinder has lost its elasticity or developed dangerous flaws. Performing a CNG Cylinder Safety Inspection is not just a legal formality but a critical safety measure to prevent catastrophic accidents on the road. The testing process typically involves removing the cylinder from the vehicle, cleaning it internally, and checking for external damage like rust or dents before subjecting it to the water jacket test. If a cylinder fails this inspection it must be destroyed immediately to ensure it never returns to circulation. Regular assessments ensure that the cylinder remains safe for use and protects both the driver and the passengers from the risks associated with high pressure gas storage. Ignoring these protocols can lead to severe penalties and life threatening situations so prioritizing these services is mandatory for responsible vehicle ownership.

Government Approved CNG Testing Center locations are the only authorized facilities where you should take your vehicle for these critical safety checks. When you search for CNG Cylinder Retesting Near Me it is vital to verify that the laboratory holds valid certifications from the Chief Controller of Explosives or relevant local authorities. Using an unauthorized center might save money initially but it puts lives at risk and usually results in a compliance plate that is not recognized by gas filling stations. A Certified Hydro Testing Lab follows strict protocols defined by safety standards to ensure every test is accurate and reliable. During the testing phase technicians look for internal corrosion which is a common issue caused by moisture and oil contaminants present in the gas. Ensuring CNG Kit Cylinder Compliance means your vehicle meets all the necessary safety norms required to refuel at CNG stations. Most regulations mandate that every CNG cylinder must undergo this testing process once every three years. Upon successful completion of the tests the center issues a compliance certificate and attaches a metal plate to the cylinder indicating the date of the test and the next due date. This documentation is often requested by traffic police and insurance companies to validate the roadworthiness of the vehicle. Therefore, selecting the right service provider is crucial for ensuring that the testing is conducted properly and that your paperwork remains valid for the next three years.

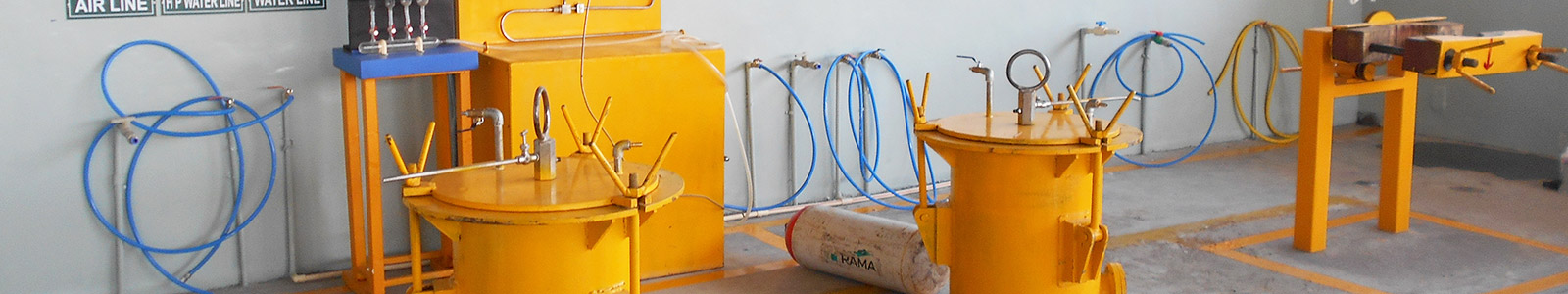

High Pressure Gas Cylinder Testing protocols are designed to assess the durability and elasticity of the metal shell under extreme conditions. The primary goal of Periodic Hydro Testing for CNG is to measure the permanent expansion of the cylinder wall after it has been pressurized. If the metal stretches beyond a safe limit and does not return to its original shape it indicates that the material has fatigued and is no longer safe for holding compressed gas. This rigorous assessment contributes significantly to CNG Cylinder Life Extension by identifying minor issues before they escalate into major failures. A standard CNG cylinder has a total lifespan of roughly twenty years but it can only reach this milestone if it passes every scheduled hydro test throughout its life. During this procedure the valve is also inspected and often replaced to prevent leaks. Once the cylinder passes the hydrostatic test it is thoroughly dried using hot air to remove any moisture that could cause rusting from the inside. The external surface is then painted to protect it from environmental corrosion. By adhering to this maintenance schedule, vehicle owners ensure that their fuel system operates efficiently and safely. Neglecting this maintenance can lead to gas leaks or cylinder bursts, which are preventable disasters. Ultimately investing time in these testing procedures guarantees peace of mind and ensures that your vehicle remains a safe mode of transport for the long term.