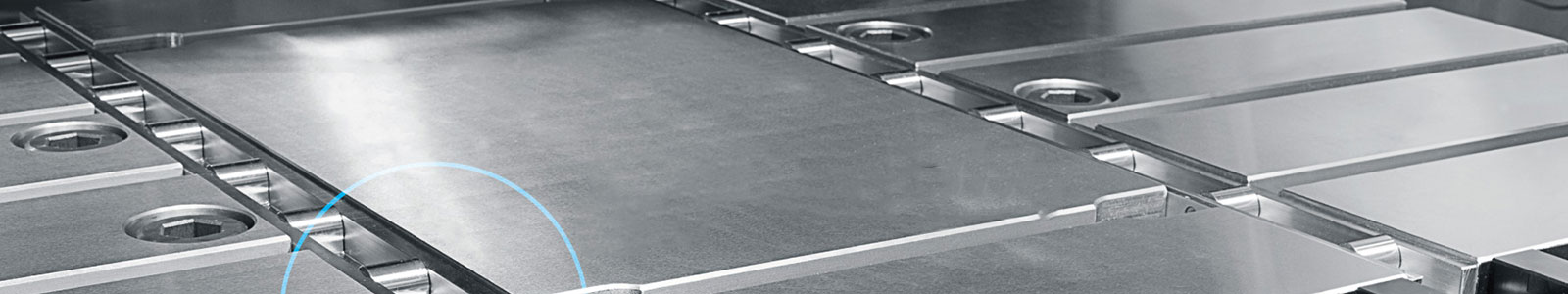

Die lifter technology is an essential component in modern manufacturing environments because it allows operators to move massive tools with minimal effort and maximum safety. When a factory manager decides to upgrade their stamping press line the primary goal is often to reduce the friction that occurs between the heavy die and the bolster table. A high quality Die lifter functions by raising the heavy tool slightly above the surface of the press bed which allows it to glide smoothly into the correct position without damaging expensive equipment. This mechanism is vital for maintaining the longevity of Industrial press tools which can suffer from severe wear and tear if they are dragged across rough surfaces repeatedly. By implementing these lifting devices companies can ensure that their valuable assets remain in pristine condition for a much longer period. Furthermore the implementation of Heavy duty die handling solutions is not just about equipment protection but also about the safety of the workforce. When employees attempt to manually push or pull heavy dies without proper lifting assistance they are at a significant risk of musculoskeletal injuries. Therefore investing in these lifting mechanisms creates a safer workplace where efficiency and employee wellbeing go hand in hand. The reduction in setup time leads to a more streamlined production process which ultimately results in higher profitability for the manufacturing plant.

Hydraulic die lifter units are specifically designed for applications where extreme force and durability are required to lift the heaviest dies in the industry. These powerful devices use fluid pressure to elevate the die and they are often preferred over a Pneumatic die lifter when the load capacity exceeds the limits of air driven systems. However the pneumatic versions are incredibly popular for cleaner environments and facilities that already have extensive air supply lines installed. For smaller operations or specific slots in the bolster plate a Spring loaded die lifter might be the most economical choice because it does not require external power sources to function effectively. Depending on the direction of movement required operators must choose between different contact styles. A Ball style die lifter is excellent for applications that require multidirectional movement allowing the die to be rotated or moved in any angle across the table. In contrast a Roller die lifter is engineered for linear movement where the die only needs to slide in and out of the press in a straight line. Selecting the correct type of lifter involves analyzing the weight of the die the available power sources and the specific movement patterns required during the changeover process. Each type offers unique advantages that cater to different sectors of the metal stamping and forming industry ensuring that every press setup can be optimized for peak performance.

Quick die change system methodologies rely heavily on the integration of these lifting components to minimize downtime between production runs. The entire philosophy of lean manufacturing depends on the ability to switch from one product to another as fast as possible and this is where the Quick die change system proves its worth. By utilizing advanced lifting technology alongside a specialized Die rolling bolster manufacturers can reduce changeover times from hours to mere minutes. The rolling bolster extends out of the press allowing cranes to load the die safely while the lifters inside the press bed prepare to receive the new tool. This seamless integration ensures that the press spends more time making parts and less time sitting idle. The return on investment for these systems is substantial because every minute saved during a die change is a minute gained in production output. Modern factories cannot afford to ignore the efficiency gains provided by these systems especially in a competitive global market where speed and agility are paramount. Proper maintenance of the lifters and the bolster ensures that the system continues to operate smoothly for years preventing unexpected breakdowns that could halt the entire production line. Ultimately the combination of lifting technology and rapid exchange protocols forms the backbone of highly efficient industrial stamping operations.