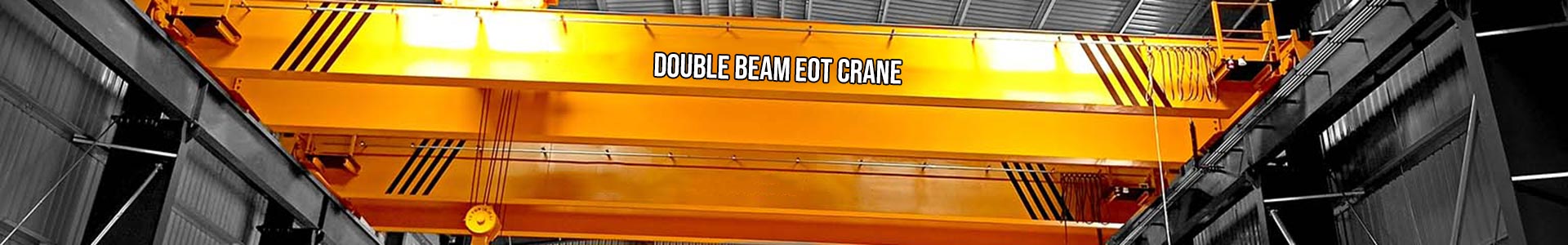

Double Beam EOT Crane serves as a vital backbone for numerous heavy industries that require absolute stability and power during daily operations. This machinery is often referred to as a Double Girder EOT Crane in technical specifications because it utilizes two parallel beams to support the lifting trolley mechanism which allows for superior load distribution compared to single beam alternatives. When businesses invest in this type of Electric Overhead Traveling Crane, they are prioritizing efficiency and safety because the dual beam structure effectively minimizes swaying and provides a higher hook height for lifting goods in facilities with limited headroom. The robust design of a Double Beam Bridge Crane allows it to span wide distances without compromising on structural integrity which makes it the preferred choice for large warehouses and manufacturing plants where heavy components must be moved with precision. Engineers design these cranes to withstand rigorous usage cycles and the separate crab mechanism traveling on top of the rails ensures that maintenance teams can easily access components for service. By implementing this robust lifting solution, companies ensure that their production lines maintain a continuous flow of materials which ultimately boosts overall operational output and minimizes downtime caused by mechanical limitations.

Double Beam EOT Crane systems are engineered specifically to function as a Heavy Duty Overhead Crane capable of operating in harsh environments such as steel mills, foundries, and heavy machinery fabrication units. The primary advantage of installing this system is its High Lifting Capacity which can range from small tonnage to hundreds of tons depending on the specific configuration and structural analysis of the building. Success in modern manufacturing relies heavily on efficient Industrial Material Handling and this crane acts as the central muscle for moving raw materials and finished products safely across the floor. These cranes often come equipped with advanced safety features including overload protection limit switches and collision avoidance systems which protect both the operators and the valuable inventory being transported. The dual girder design offers excellent lateral rigidity which is essential when the crane accelerates or decelerates quickly with a heavy load attached to the hook. Furthermore, the walkway installed along the girder allows maintenance personnel to inspect the crane safely without needing additional aerial work platforms which simplifies the upkeep of the entire lifting system and prolongs the lifespan of the equipment.

Double Beam EOT Crane selection involves a detailed consultation with a professional Crane Manufacturer to ensure that the chosen model aligns perfectly with the unique spatial dimensions and workflow requirements of a facility. Many buyers opt for a Customized EOT Crane that features specialized hoists, variable frequency drives for smooth motion control, and automated positioning systems to enhance precision during assembly tasks. As a critical piece of Material Handling Equipment, the crane must be reliable and durable to justify the capital expenditure involved in its purchase and installation. Business owners should also evaluate the Double Girder Crane Price in relation to the long term value it brings through reduced labor costs and faster turnaround times for heavy lifting tasks. Investing in a high quality double beam system guarantees that a facility can handle future production increases without needing to upgrade their lifting infrastructure repeatedly. The combination of electrical efficiency and mechanical strength makes these cranes an indispensable asset for any sector that deals with substantial weight and requires a lifting solution that delivers consistent performance year after year without failure.