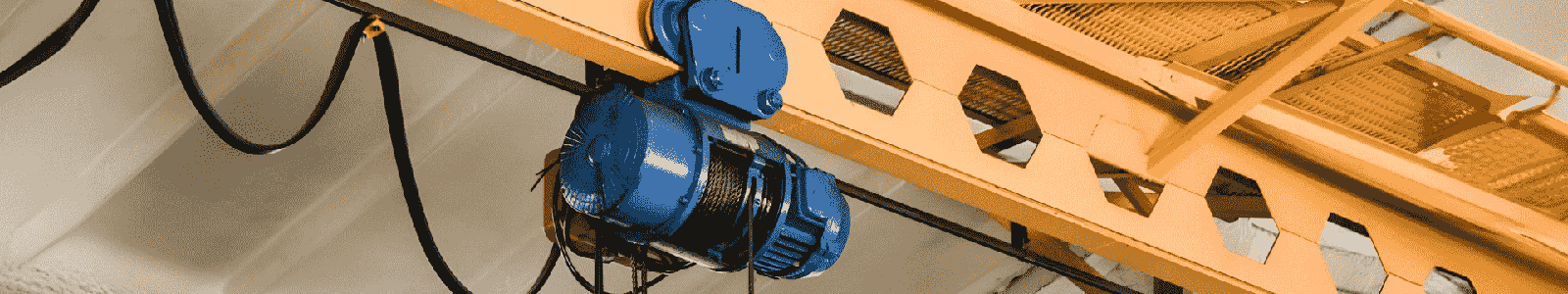

Electric Hoist Motors serve as the beating heart of modern industrial operations because they provide the necessary torque and power required to lift massive loads with precision and safety. These electromechanical devices are engineered to convert electrical energy into mechanical power which enables the vertical movement of goods in factories warehouses and construction sites worldwide. When companies look for the best machinery they often prioritize Industrial Crane Motors that are designed to withstand high operational cycles and harsh environmental conditions including extreme heat and dust accumulation. The efficiency of a lifting operation depends heavily on the specification of the motor because an underpowered unit can lead to catastrophic failure while an overpowered unit results in unnecessary energy consumption and increased operational costs. In the realm of logistics and manufacturing the demand for Heavy Duty Lifting Equipment has surged because businesses aim to maximize productivity without compromising on safety standards. Engineers must calculate the duty cycle and load factor carefully before selecting a motor to ensure that it can handle the specific demands of the task at hand. The integration of advanced cooling systems within these motors helps in dissipating the heat generated during frequent starts and stops which is a common characteristic of lifting operations. By focusing on robust design and high quality materials manufacturers ensure that these motors deliver consistent power output which is crucial for maintaining the workflow in assembly lines and shipping yards. The selection process for these motors involves analyzing the speed torque curve to match the requirements of the hoist mechanism perfectly. This attention to detail ensures that the entire system operates smoothly and reduces the mechanical stress on gears and brakes thereby extending the overall lifespan of the machinery.

Hoist Motor Maintenance is absolutely critical for ensuring the longevity and safety of lifting operations because neglect can lead to sudden breakdowns and costly downtime for industrial facilities. A comprehensive maintenance schedule should include regular inspections of the brushes bearings and windings to detect early signs of wear and tear which could escalate into major failures if left unaddressed. Implementing robust Material Handling Solutions requires a holistic approach where the motor is viewed not just as a standalone component but as an integral part of a larger ecosystem that moves products efficiently from one point to another. The synergy between the motor and the gearbox is vital for Overhead Crane Systems which dominate the skyline of large manufacturing plants and shipping ports. These systems rely on the precise control of the motor to position heavy loads with millimeter accuracy which minimizes the risk of damage to the goods and ensures the safety of the operators working on the ground. Modern setups increasingly utilize Variable Frequency Drives to control the speed and torque of the motor with exceptional precision allowing for soft starts and stops that reduce the mechanical shock on the structure. This technology not only improves the handling characteristics of the crane but also contributes to significant energy savings by matching the power consumption to the actual load requirements. Regular testing of the insulation resistance and vibration analysis are standard practices in predictive maintenance programs which aim to identify potential issues before they cause a stoppage in production. By investing in proactive care and utilizing advanced diagnostic tools facility managers can ensure that their lifting equipment remains in peak condition and continues to support the operational goals of the organization without interruption.

Slip Ring Induction Motors are frequently chosen for applications requiring high starting torque and adjustable speed control because they offer distinct advantages over other motor types in heavy lifting scenarios. These motors utilize a wound rotor connected to external resistors through slip rings, allowing operators to modify the resistance and thereby control the starting current and torque characteristics effectively. While Squirrel Cage Motors are known for their rugged construction and low maintenance requirements they sometimes lack the starting torque needed for starting under very heavy loads which makes the slip ring design superior for certain massive hoist applications. The choice between these two types of motors depends largely on the specific requirements of the application including the frequency of operation the magnitude of the load and the available power supply infrastructure. Achieving Reliable Hoist Performance requires a deep understanding of these electrical characteristics and how they interact with the mechanical components of the hoist such as the drum and the wire rope. Engineers must also consider factors such as the ambient temperature and altitude which can affect the cooling efficiency and power output of the motor. The evolution of motor technology continues to bring forth innovations such as permanent magnet motors and smart sensors that provide real time data on the health of the machine. This data driven approach allows for better decision making and optimization of the lifting process. Ultimately the goal is to create a lifting system that is not only powerful and efficient but also safe and dependable ensuring that industrial operations can proceed without the fear of equipment failure. The proper matching of the motor to the application is the cornerstone of successful material handling and safeguards the investment made in these complex and essential machines.