Key Factors to Consider When Partnering with a Transformer Supplier in India

Selecting the right transformer supplier is crucial for ensuring reliability, efficiency, and long-term cost savings. Indian manufacturers offer diverse solutions, but businesses must evaluate key factors before forming a partnership.

- Product Quality and Reliability: Ensure the supplier uses high-grade materials and advanced manufacturing techniques. Reliable transformers reduce downtime, maintenance costs, and energy losses, supporting smooth operations and long-term performance.

- Compliance with Industry Standards: Check for adherence to international and Indian standards like IEC, IS, and ISO. Compliance ensures safety, energy efficiency, and suitability for both domestic and global applications.

- Customization Capabilities: A good supplier should offer tailor-made transformer solutions to meet specific voltage, load, or industry requirements, ensuring optimized performance for unique operational needs.

- Experience and Industry Reputation: Partner with suppliers who have proven experience and positive client feedback. Established manufacturers bring technical expertise, consistent quality, and reliable after-sales support.

- After-Sales Support and Maintenance: Strong technical support, maintenance services, and prompt issue resolution are essential. Suppliers who provide responsive service help minimize downtime and ensure long-term reliability.

- Cost-Effectiveness and Transparent Pricing: Evaluate pricing structures, bulk order discounts, and overall cost efficiency. Transparent pricing without hidden charges ensures predictable procurement budgets and better ROI.

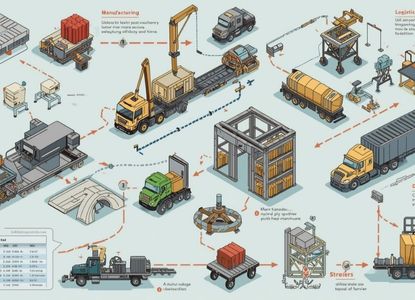

- Delivery Timelines and Supply Chain Reliability: Ensure the supplier can meet project deadlines and handle logistics efficiently. Reliable delivery reduces production delays and strengthens operational planning.