Latest Trends and Innovations in Gasket Manufacturing

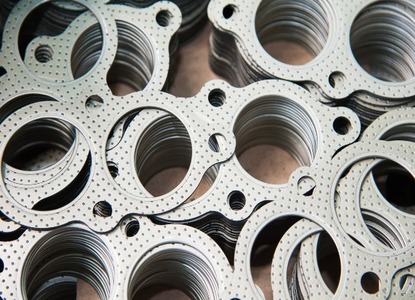

Gasket manufacturing is evolving with advanced materials, precision engineering, and smart technologies. These innovations improve sealing performance, durability, and sustainability, meeting the growing demands of modern industrial applications.

- Advanced Material Development: Manufacturers are using high-performance materials like expanded graphite, PTFE composites, and metal alloys to improve resistance to heat, pressure, and chemical exposure.

- Custom-Engineered Gaskets: Customized gaskets designed for specific applications improve sealing accuracy, reduce failure risks, and enhance overall equipment performance in specialized industrial environments.

- Improved Manufacturing Precision: Modern CNC machines and laser cutting technologies ensure precise gasket dimensions, uniform thickness, and better surface finishes for reliable and consistent sealing.

- Focus on Sustainability: Eco-friendly materials and low-emission manufacturing processes are gaining importance, helping industries reduce environmental impact while maintaining high sealing performance.

- Smart Gasket Technologies: Innovations include sensor-enabled gaskets that monitor pressure and temperature, helping detect leaks early and enabling predictive maintenance strategies.

- Enhanced Testing and Quality Control: Advanced testing methods ensure gaskets meet strict performance standards, improving reliability and reducing failures in high-stress applications.

- Industry-Specific Solutions: Manufacturers now design gaskets tailored to industries like oil and gas, pharmaceuticals, and renewable energy, ensuring better compatibility and long-term performance.