Air Pollution Control Devices are necessary instruments in the ongoing attempt to reduce the negative impacts of industrial emissions and to ensure the health of our environment. These advanced systems are designed to neutralise, capture, or eliminate pollutant-laden air from Delhi and beyond before it is released into the air. Utilised in a wide range of industries, including power generation and manufacturing, the systems provide crucial protection against air pollution. The choice and application of the right techniques to reduce air pollution are essential for companies trying to comply with strict environmental regulations and help to ensure improving the quality of air throughout Delhi as well as other urban areas. If you are a business looking for reliable solutions, collaborating with a trusted air pollution control device manufacturer located in Delhi is an essential step in achieving successful pollution management. In the same way, partnering with a reliable air pollution control equipment supplier in Delhi provides access to the required equipment and continuous assistance.

Air Pollution Control Devices encompass an array of different technologies that are designed to tackle specific kinds of pollutants produced through various industrial processes. Plants that power, for example, depend on these devices to limit emissions of sulphur dioxide, nitrogen oxides, and particulate matter from the burning of fossil fuels. Manufacturing industries, like steel, cement and chemical plants, employ these systems to remove particles, gases that are toxic and chemical vapours that are produced by their activities. Petroleum refineries utilise scrubbers and filters that effectively get rid of VOCs (VOCs) and other dangerous air pollutants. Many industries, including paint manufacturing and automotive, use controls to control the fumes, solvents and airborne particles that are generated by their production processes. Food processing facilities and pharmaceutical facilities rely on oxidation and air filtration technologies to get rid of odours as well as chemical byproducts, demonstrating the versatility of these vital technologies. The introduction of advanced technologies for controlling air pollution in Delhi is a sign of a growing commitment to environmental sustainability.

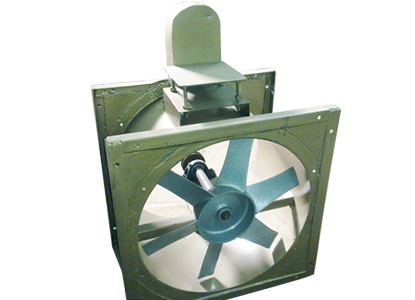

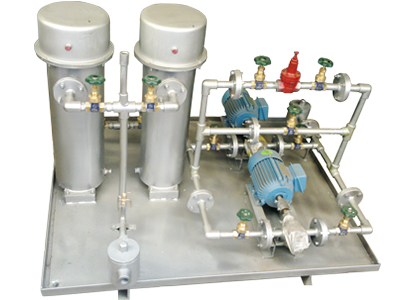

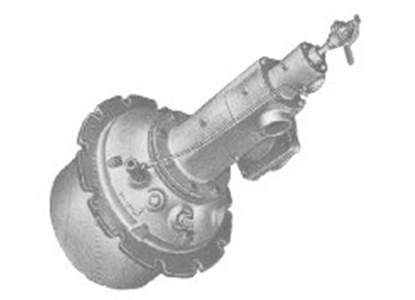

Air Pollution Control Devices are available in a variety of configurations, each of which employs unique mechanisms to target particular kinds of airborne contaminants. To remove particles, the most common techniques include baghouse filters that effectively trap dust particles cyclone separators that use centrifugal force to remove parts from the stream of gas electrostatic precipitators, which employ electrical charges to draw and capture particulate matter. To deal with gas emissions, such as VOCs and sulphur dioxide, industries typically employ wet and dry scrubbers that use liquid or solid sorbents that take in or react to pollutants, as well as activated carbon filters that absorb gaseous pollutants. They also use thermal oxidisers to eliminate VOCs and other gases that are combustible by high-temperature combustion. The choice of high-quality scrubbers in Delhi, for instance, is vital for companies which have a significant amount of gas emissions. Furthermore, the incorporation of these devices in the most efficient air handling systems in Delhi assures complete pollution control and is a significant contribution to the health of the public and environmental preservation. Often, they are affordable air filtration systems in Delhi when evaluating the long-term advantages.