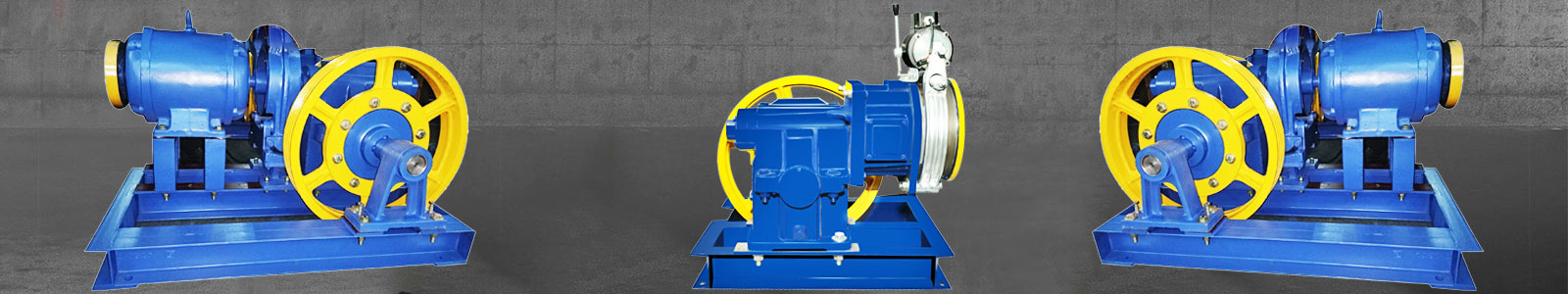

Motor Coupling is a critical component that connects the elevator motor to the gearbox, allowing smooth power transmission and minimizing vibrations that can affect ride comfort. The Elevator Traction Wheel interacts with suspension ropes to lift and lower the cabin accurately while maintaining alignment within the shaft. Regular application of high-quality Gear Lubricant ensures that all moving parts operate efficiently, reducing friction and preventing premature wear of the gearbox and pinion gears. A precisely engineered Bevel Gear provides smooth angular motion, enabling the elevator system to manage directional changes in mechanical assemblies without loss of torque. Finally, a reliable Speed Reducer allows the elevator to maintain controlled acceleration and deceleration, enhancing passenger comfort and ensuring compliance with safety regulations. Integrating these five components into content emphasizes their importance for system efficiency and longevity. When property managers or technicians search for solutions to optimize elevator performance, content that covers motor couplings, traction wheels, lubrication practices, bevel gears, and speed reducers provides practical guidance. Highlighting these keywords not only improves SEO but also educates readers on best practices for elevator gear maintenance. By understanding the function of each component, users can reduce operational downtime, enhance ride quality, and ensure elevators remain safe for daily use.

Elevator Gear remains a foundational element in any vertical transport system, particularly when combined with a robust Elevator Traction Wheel for precise cabin movement. A well-maintained Gearbox Assembly continues to ensure smooth torque transmission, while the Pinion Gear provides consistent speed control across all operating conditions. Regular inspection of the Worm Gear is essential to avoid wear and maintain smooth motion under heavy loads. Additionally, the Motor Coupling plays a vital role in linking the motor to the drivetrain, ensuring that power is delivered efficiently without vibration or energy loss. Together, these components contribute to elevator reliability, energy efficiency, and passenger safety. SEO-focused content that emphasizes these keywords helps building managers, service technicians, and engineers understand the interaction between elevator gear components. Detailed descriptions of gearbox functionality, worm gear maintenance, and motor coupling benefits provide actionable insights for system optimization. When elevator systems operate with properly maintained traction wheels, pinion gears, and motor couplings, both efficiency and safety are enhanced. Highlighting these key parts in structured content also increases search visibility for professionals seeking guidance on elevator gear installation, servicing, and maintenance. Combining technical explanations with practical applications ensures that readers gain a complete understanding of how elevator gear components work together to deliver reliable vertical transportation solutions.