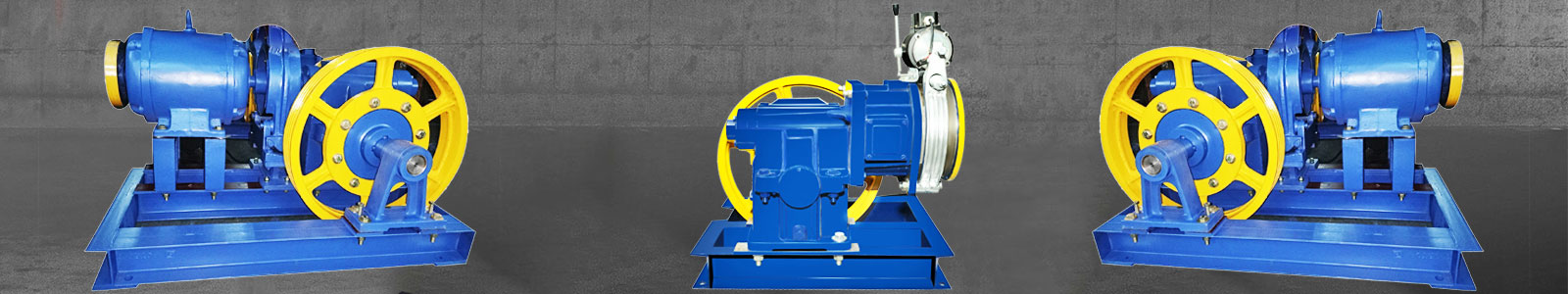

Gear Lubricant is essential for minimizing friction and wear within the elevator gearbox, ensuring that all moving parts operate efficiently and maintain long service life. A reliable Motor Coupling connects the elevator motor to the gearbox, allowing smooth power transmission without energy loss or vibration. The Traction Wheel interacts with suspension ropes to move the elevator cabin accurately while maintaining tension and alignment within the shaft. Incorporating a high-quality Speed Reducer helps control elevator acceleration and deceleration, improving passenger comfort and system safety. Finally, the Gear Housing protects internal components from dust, debris, and environmental factors while providing structural stability for the entire gearbox assembly. Highlighting these keywords in SEO-friendly content informs building managers, service technicians, and elevator engineers about the importance of lubrication, coupling efficiency, traction wheel integrity, speed reduction, and protective housing. Understanding the role of each part helps prevent operational issues, reduces maintenance frequency, and ensures compliance with safety regulations. Well-structured content emphasizing these elements can improve search visibility for those seeking practical insights into elevator gearbox operation, installation, and servicing best practices.

Elevator Gear Box continues to be the foundation of safe and efficient elevator performance, particularly when paired with a properly maintained Traction Wheel that ensures precise cabin movement. Regular application of Gear Lubricant minimizes wear on the Worm Gear and Bevel Gear, ensuring consistent torque transmission and smooth motion under heavy loads. A well-aligned Motor Coupling further guarantees efficient power transfer from the motor to the drive system, reducing vibration and energy loss. Additionally, the Speed Reducer plays a critical role in controlling acceleration and braking, enhancing passenger comfort and system safety. Together, these components form an integrated elevator gearbox system where each part supports the others, reducing downtime and increasing reliability. SEO-focused content that emphasizes these keywords educates engineers, service technicians, and property managers on maintenance routines, component selection, and performance optimization. By highlighting the interdependence of worm gears, bevel gears, traction wheels, motor couplings, and speed reducers, readers gain a complete understanding of how elevator gearboxes operate. Proper installation, lubrication, and alignment ensure maximum efficiency, longevity, and compliance with safety standards. Structured content that clearly explains these critical parts not only supports SEO goals but also provides actionable insights for elevator professionals seeking to enhance system performance and passenger safety.