Crane Coupling devices serve as the critical interface in heavy machinery ensuring that the rotational force generated by motors is effectively transferred to the gearboxes and lifting drums without failure. These components are fundamental to the operation of overhead cranes gantry cranes and jib cranes found in manufacturing plants and shipping ports globally. When companies source Industrial Crane Parts they must look for components that offer exceptional durability because the stress applied during lifting operations is immense. The process of Mechanical Power Transmission relies heavily on the quality of the connection between the driving and driven shafts. If a coupling fails it results in immediate downtime and poses severe safety risks to workers on the ground. Engineers design these couplings to absorb shock loads and dampen vibrations which protects the motor and gearbox from damage during sudden starts or stops. A key performance metric for these components is their ability to handle High Torque Transmission requirements especially when lifting shipping containers or molten metal ladles. The physics behind this involves transferring rotational energy while accommodating slight variations in shaft positioning. Without robust couplings the machinery would suffer from rapid wear and tear, leading to expensive replacements and operational delays. High quality steel and advanced heat treatment processes are often used in manufacturing these couplings to ensure they can withstand harsh industrial environments including high temperatures and dust contamination. Therefore selecting the correct coupling specification is the first step toward building a reliable and safe lifting mechanism.

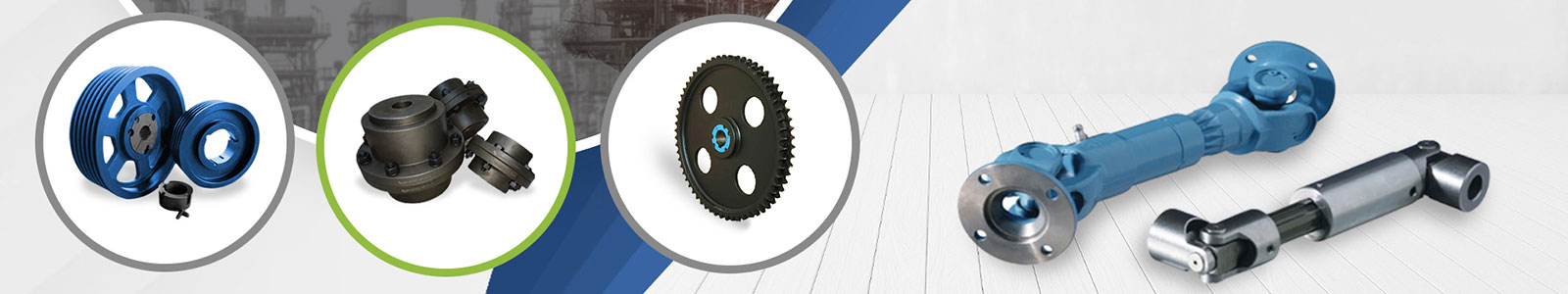

Heavy Duty Couplings are specifically engineered to withstand the rigorous demands of continuous industrial operations where standard components would quickly deteriorate under the strain. Among the various types available the Drum Coupling is widely utilized in crane lifting mechanisms to connect the gearbox output shaft to the rope drum. This specific type of coupling is designed with spherical rollers or barrel shaped teeth that allow it to transmit torque while accommodating angular misalignment caused by the deflection of the rope drum. Another essential variant is the Flexible Gear Coupling which uses a sleeve and hub arrangement with gear teeth to transmit power. This design is favored for its high power density and ability to compensate for angular parallel and axial misalignments that occur during operation. Implementing effective Shaft Alignment Solutions is crucial because even minor deviations in alignment can generate excessive heat and vibration eventually destroying seals and bearings. By using couplings that offer some degree of flexibility maintenance teams can ensure that the machinery runs smoothly even if the foundation settles slightly over time. These heavy duty components act as a safety fuse in the drive train protecting more expensive equipment like motors and gearboxes from catastrophic failure. Industries such as mining metallurgy and logistics depend on these robust connections to maintain high throughput and meet tight production schedules. The correct application of these couplings ensures that the crane operates within its design parameters reducing the risk of structural fatigue.

Hoist Drive System efficiency depends entirely on the integrity of every mechanical connection within the assembly making the choice of coupling a matter of operational necessity. The drive system is responsible for the vertical movement of loads and any interruption here can have serious financial implications for a business. To keep these systems running at peak performance facility managers must invest in professional Coupling Maintenance Services which include regular inspections for wear lubrication checks and alignment verification. Proper lubrication is vital for gear and drum couplings as it reduces friction between the mating surfaces and dissipates heat generated during operation. Neglecting maintenance often leads to the development of pitting or spalling on the gear teeth which compromises the strength of the connection. A well maintained system ensures that the transfer of power remains constant and smooth preventing the load from jerking or swinging dangerously during transport. Advanced monitoring technologies are now being integrated into drive systems to predict when a coupling might fail allowing for preventative replacement during scheduled shutdowns rather than emergency repairs. By prioritizing the health of the drive system and its connecting parts, companies can significantly extend the lifespan of their cranes. This proactive approach to asset management not only saves money on spare parts but also ensures compliance with strict industrial safety regulations regarding lifting equipment. Ultimately the reliability of the entire crane hinges on the correct selection installation and care of these vital connecting links.