End Carriage stands as the fundamental foundation for the movement of overhead cranes and acts as the driving force that allows the bridge girder to travel along the runway beams efficiently. This structural assembly consists of a rigid steel frame that houses the wheels and drive assembly which are critical for the smooth operation of the entire lifting mechanism in various industrial environments. Engineers design these units to withstand high loads and continuous stress which ensures that the crane remains stable during the transportation of heavy materials across factory floors or warehouses. The robustness of the structure is often compared to a Crane End Truck which is a term frequently used in different regions to describe the exact same assembly that supports the bridge. When industries look for reliable lifting solutions they must prioritize the quality of these carriages because any misalignment or structural weakness can lead to excessive wear on the rails and potential safety hazards during operations. A well manufactured carriage ensures minimal maintenance downtime and maximizes the lifespan of the crane system. It is essential for facility managers to understand that investing in high quality Material Handling Equipment such as precision engineered carriages significantly boosts productivity by reducing the risk of mechanical failure. The integration of high grade steel and precision machining in the manufacturing process of these carriages guarantees that they can handle the dynamic loads imposed during the acceleration and deceleration of the crane.

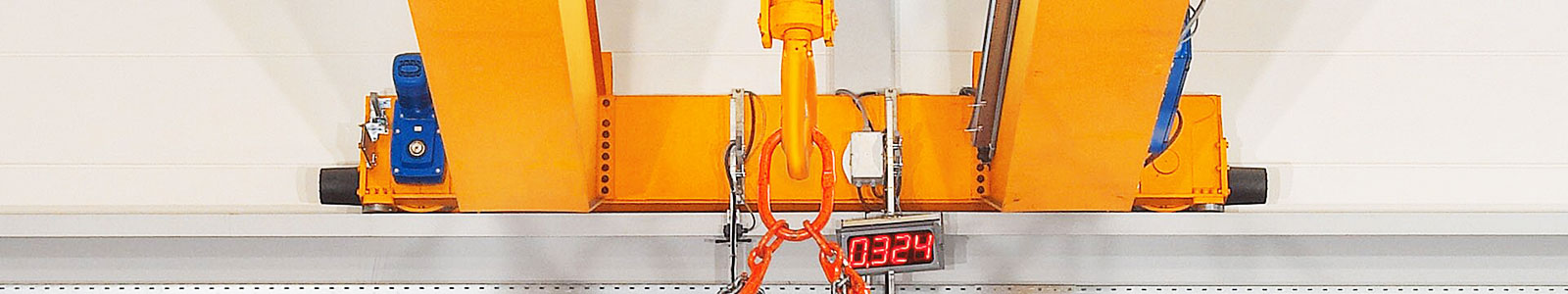

Single Girder End Carriage configurations are specifically designed for lighter loads and shorter spans where the crane bridge consists of one main beam and these units offer a cost effective solution for many small to medium sized workshops. In contrast to the lighter setups the industrial sector often requires more robust solutions like the Double Girder End Carriage which supports two main beams and is engineered to handle significantly heavier lifting capacities and wider spans found in large steel plants or shipyards. These heavy duty versions distribute the weight of the load more evenly across the runway rails which reduces the pressure on individual wheels and enhances the overall stability of the lifting operations. Modern crane systems have evolved to include sophisticated drive mechanisms known as Motorized End Carriages that utilize electric gear motors to provide smooth and controlled acceleration which eliminates the jerky movements associated with older manual systems. The efficiency of these motorized units relies heavily on the EOT Crane Wheel System which must be perfectly aligned to prevent skewing and ensure that the crane travels in a straight line without causing damage to the runway rails. This wheel system usually includes hardened steel wheels that are resistant to wear and tear which is crucial for facilities that operate their cranes on a twenty four hour basis. Selecting the correct type of carriage and drive system is a critical decision that impacts the long term operational costs and safety of the facility.

Overhead Crane Components encompass a wide range of parts but few are as critical to the daily function of the crane as the wheel blocks and end carriages because they bear the entire weight of the suspended load and the crane structure itself. A vital sub assembly within this system is the Crane Wheel Block which allows for easy maintenance and rapid replacement of wheels without the need to dismantle the entire carriage structure. These modular blocks are designed for easy alignment and installation which helps maintenance teams keep the crane running with minimal interruption to production schedules. When sourcing replacements or upgrading existing machinery it is imperative to select Heavy Duty Crane Parts that meet international safety standards to ensure they can withstand the rigorous demands of industrial lifting. The durability of these parts directly correlates to the safety of the workers operating the machinery and the protection of the valuable goods being transported. Manufacturers focus on creating sealed bearing housings and self lubricating systems within the carriage to prevent dust and debris from entering the moving parts which is especially important in harsh environments like foundries or cement plants. By focusing on the quality and compatibility of these specific components companies can ensure their overhead cranes deliver optimal performance for decades. The correct combination of a sturdy frame precise wheels and powerful motors creates a synergy that defines the modern efficiency of industrial material handling.