Crane Wheel Assembly is the fundamental component that dictates the efficiency and safety of moving heavy loads across a facility track system. When engineers design lifting mechanisms they must prioritize precision to ensure that the entire machine operates smoothly without causing excessive wear on the rails. A robust assembly supports the massive weight of the load and transfers it effectively to the track surface. In many large factories and warehouses the demand for Industrial Crane Wheels is high because they facilitate the daily operations of logistics and production lines. If a wheel fails it can halt production completely which results in significant financial losses for the company. Therefore choosing high quality components is vital for maintaining continuous workflow. These assemblies must withstand extreme pressure and friction which is why Heavy Duty Crane Wheels are specifically engineered to handle aggressive environments and substantial tonnage. The heat treatment process applied to these wheels determines their surface hardness and depth which directly impacts their resistance to wear and fatigue. Proper alignment of the assembly is also critical because misalignment can lead to flange breakage and rapid deterioration of the rail system. Regular inspection of the tread and flanges ensures that the wheels maintain proper contact with the rail which prevents derailment risks. By investing in superior wheel assemblies companies ensure the longevity of their infrastructure and the safety of their workforce. The steel used in these components is often alloyed to provide additional toughness and durability against impact loads that occur during lifting operations.

Overhead Crane Wheels function as the critical interface between the crane bridge and the runway rails allowing for horizontal movement across the span of the building. These components are subjected to high rolling contact fatigue and must be manufactured with exact tolerances to ensure smooth travel. Among the various manufacturing methods Forged Crane Wheels are widely preferred over cast versions because the forging process aligns the grain structure of the metal which significantly enhances its strength and structural integrity. This internal structure makes forged options less susceptible to cracking under heavy impact or shock loading conditions. While overhead systems are common inside buildings Gantry Crane Wheels are frequently utilized for outdoor applications where the crane moves on rails installed at ground level. These wheels face different challenges such as exposure to environmental elements like rain and dust which can accelerate corrosion and wear. To combat this manufacturers apply special surface treatments and utilize sealed bearings to protect the internal mechanisms. These wheel types are integral parts of larger Material Handling Equipment systems that define the operational capacity of ports, steel mills, and construction sites. The selection of the correct wheel diameter and material grade depends on the specific duty cycle of the crane and the maximum load it is expected to carry. Using the wrong type of wheel can lead to premature rail wear, which is much more expensive to repair than the wheel itself. Thus understanding the operational environment is key to selecting the right wheel type.

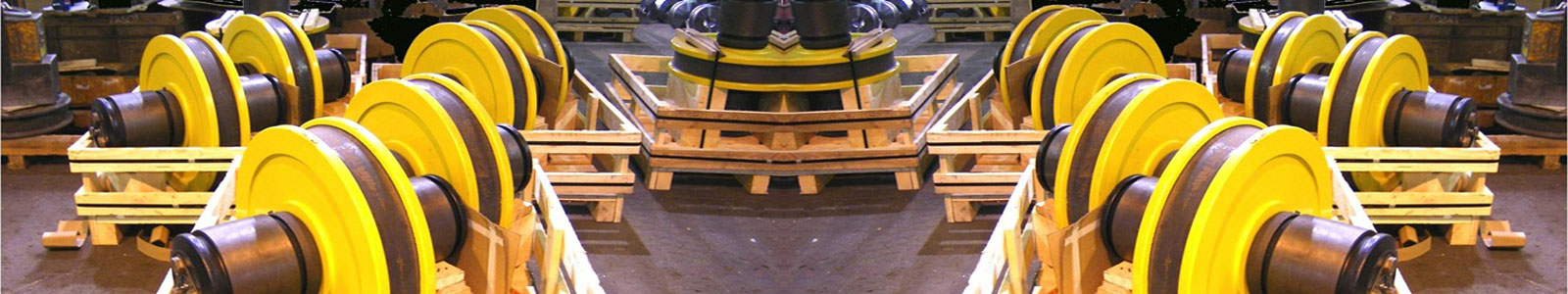

Crane Wheel Block systems offer a modular solution that simplifies the installation and maintenance of travel units on various types of lifting machinery. These self contained units include the wheel, bearings, and housing which makes alignment easier and reduces the time required for assembly on site. Even with the best maintenance practices components eventually reach the end of their service life and require Crane Wheel Replacement to restore the machine to optimal performance. Recognizing the signs of wear such as flat spots on the tread or thinning flanges, is essential for scheduling timely maintenance before a catastrophic failure occurs. When sourcing new parts it is crucial to partner with a reputable Crane Wheel Manufacturer who can provide certified components that meet international safety standards. A reliable manufacturer will offer customization options to match the specific rail dimensions and hardness requirements of the existing system. They can also provide technical advice on how to upgrade the wheel material to extend the service intervals. Replacing a wheel is not just about swapping parts it is an opportunity to inspect the axle and bearings for damage that might have caused the failure. Proper lubrication and regular audits of the wheel condition will significantly extend the life of the crane. Ultimately the goal is to achieve a balance where the wheel is tough enough to carry the load but not so hard that it damages the rail. This delicate balance ensures sustainable operation and cost effectiveness for any industrial facility relying on heavy lifting machinery.