Crane Winches are the fundamental components in the material handling and engineering sectors because they provide the necessary force to lift and pull heavy objects with extreme precision and stability across various industries. When businesses search for reliable lifting solutions they often compare different power sources to find the best fit for their specific environment and operational needs. The Hydraulic Winch is frequently selected for operations requiring immense power and continuous duty cycles because it utilizes fluid power to generate high torque which is essential for maritime and mining applications where electricity might be unstable or unavailable. This type of equipment is renowned for its ability to function under water or in explosive environments without the risk of sparking. On the other hand the Electric Winch offers a cleaner and more convenient alternative for workshops and smaller construction sites where electrical power is readily accessible and ease of installation is a priority. These devices transform electrical energy into mechanical pulling force making them ideal for intermittent use and precision tasks where fine control is required. Whether you choose a fluid power system or an electrically driven motor the primary goal remains efficient vertical lifting or horizontal pulling without failure. Understanding the power source is the first step in selecting the right machine for your project ensuring that the equipment can handle the rigors of daily use. Regular maintenance of these systems ensures longevity and reduces downtime which is critical for profitability in logistics and heavy engineering sectors. The choice between these two types often depends on the available infrastructure and the specific intensity of the work required at the job site.

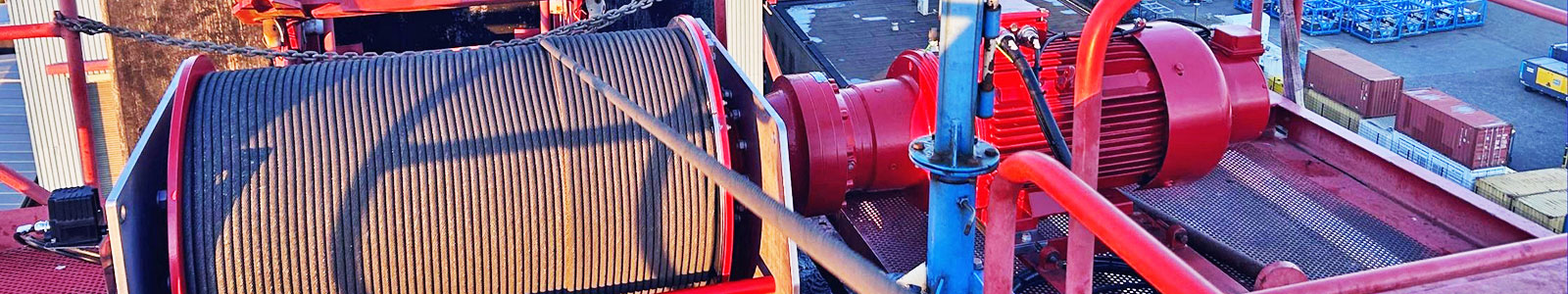

Industrial Lifting Equipment plays a vital role in the global supply chain by enabling the movement of massive containers and machinery that human labor simply cannot manage alone. A Heavy Duty Hoist system is designed to withstand extreme conditions including high temperatures and dust filled environments while maintaining peak performance levels during repetitive lifting tasks. These powerful machines rely heavily on the integrity of the Wire Rope Winch component which features multi strand steel cables capable of resisting abrasion and crushing forces under tension. The durability of the wire rope dictates the overall safety of the lift and requires frequent inspection to detect wear and tear before it becomes a hazard to the workforce. Inside the casing of high performance models you will often find a Planetary Gear Winch mechanism which uses a central sun gear surrounded by planet gears to distribute the load evenly. This gearing design is preferred by engineers because it offers a compact size with a high torque output and great efficiency making it perfect for cranes that have limited installation space but need to lift massive weights. The synergy between the strong cable and the efficient gearing system allows industries to move raw materials and finished goods safely and quickly across large distances within a facility. Without these specialized gears and ropes the efficiency of modern ports and factories would significantly decrease leading to slower production times and increased operational costs. Therefore investing in high quality gearing and hoisting components is essential for maintaining a competitive edge in the industrial market.

Construction Machinery Parts must adhere to strict regulatory standards because the failure of a single component on a busy job site can lead to catastrophic consequences for workers and valuable infrastructure. To mitigate risks and ensure smooth operations manufacturers integrate advanced Winch Safety Mechanisms such as automatic braking systems and emergency stop functions that engage immediately if power is lost or control is compromised. These safety features are non negotiable in sectors where human lives are at risk during vertical lifting operations. Furthermore operators must strictly observe the Load Capacity of the equipment which refers to the maximum weight the winch can safely handle without structural failure or mechanical breakdown. Exceeding the rated capacity is the leading cause of crane accidents so modern systems often include load limiters and electronic monitoring displays to warn the operator when the weight approaches the danger zone. By respecting these limits and utilizing high quality components construction firms ensure that projects proceed on schedule without costly interruptions or safety violations. Training operators to understand the limits of their machines is just as important as the hardware itself. When the correct protocols are followed the lifespan of the equipment increases significantly and the return on investment is maximized for the construction company. The proper selection and use of these winching systems ultimately define the success and safety of heavy infrastructure projects around the globe.