Electric Chain Hoist technology has revolutionized the way modern factories and warehouses manage their daily operations by providing a reliable and efficient method for vertical movement. When a business owner decides to upgrade their facility they often look for machinery that offers precise control and durability. An electric model is preferred in many workshops because it provides smooth lifting action which helps in preventing damage to fragile loads during transit. While the chain version is excellent for standard loads many industries also rely on the Wire Rope Hoist for operations that require faster lifting speeds and higher elevations. The wire rope design consists of a drum that winds a steel cable to lift the hook and it is often found in heavy manufacturing plants where speed is crucial for productivity. One of the most critical factors when selecting between these two types is determining the required Lifting Capacity for the specific tasks at hand. If a facility needs to lift extremely heavy items weighing several tons a wire rope system is usually the better choice due to its strength and resistance to fatigue. However for lighter loads and frequent cycling the chain hoist remains a cost effective and robust option. Engineers design these hoists with safety brakes and limit switches to ensure that the load never exceeds safe parameters. Correctly matching the hoist to the load ensures that the motor operates within its optimal range and prevents premature wear on the internal components. It is vital for operators to understand the weight limits of their equipment to maintain a safe working environment for everyone on the floor.

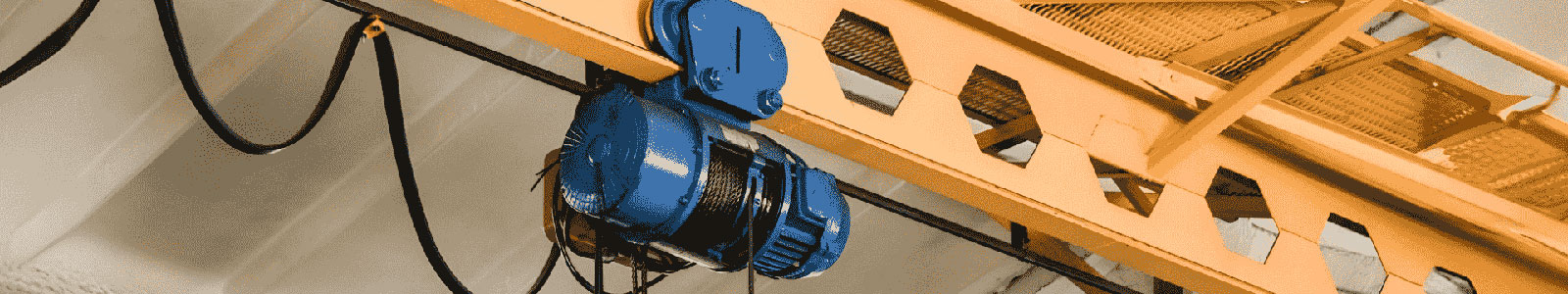

Heavy Duty Lifting requirements in sectors such as steel production and shipping demand infrastructure that goes beyond simple hoists and usually involves comprehensive structural solutions. To facilitate the movement of massive loads across a large rectangular area most large factories install Overhead Crane Systems that run on elevated runway beams. These systems allow the hoist to move in three dimensions providing complete coverage of the floor space below which is essential for assembly lines and storage yards. As a fundamental part of Industrial Lifting Equipment these cranes are engineered to withstand rigorous use and harsh environmental conditions including heat and dust. When a permanent overhead runway is not feasible or if the lifting needs are located outdoors a Gantry Crane serves as an excellent alternative solution. A gantry system features legs that move on wheels or rails along the floor making it a versatile option for shipyards or construction sites where flexibility is key. These powerful machines enable workers to transport raw materials and finished goods with minimal physical effort which significantly reduces the risk of workplace injuries. The structural integrity of a gantry or overhead system relies on high quality steel and precision engineering to handle the dynamic forces generated during operation. By investing in these robust lifting frameworks companies can streamline their logistics and ensure that heavy materials move seamlessly through the production cycle without causing bottlenecks or delays.

Material Handling Solutions encompass a broad strategy that aims to optimize the workflow and enhance the safety of goods movement within a commercial space. While large cranes cover the main areas there is often a need for localized lifting at specific workstations and this is where the Jib Crane becomes highly effective. A jib crane typically consists of a horizontal boom attached to a wall or a floor pillar which allows for rotational movement and precise positioning of loads over a smaller radius. This type of equipment is perfect for assisting machine operators who need to load heavy parts onto a lathe or a milling machine repeatedly throughout the day. However even the most advanced machinery will eventually suffer from wear and tear which makes regular Hoist Maintenance an absolute necessity for long-term operational success. Routine inspections of the hooks cables brakes and motors help in identifying potential issues before they lead to catastrophic failures. A proactive maintenance schedule ensures that the equipment remains in compliance with safety regulations and extends the lifespan of the asset significantly. Ignoring small signs of damage like frayed wires or unusual noises can lead to expensive repairs and dangerous accidents that halt production. Therefore implementing a strict protocol for checking and servicing all lifting gear is just as important as buying the right equipment in the first place. By combining the correct cranes with diligent care, businesses create a productive environment where safety and efficiency go hand in hand.