Electric Wire Rope Hoist technology serves as the fundamental powerhouse within the lifting industry and it drives the vertical movement required in factories and warehouses globally. When facility managers integrate a Double Girder Overhead Crane into their infrastructure they utilize these robust crab units to travel along the bridge girders for precise load positioning. The structural integrity of a Heavy Duty Crab Unit is specifically engineered to withstand harsh environments, including steel mills and foundries where extreme heat and dust are common challenges. These machines play a critical role in Industrial Material Handling by allowing operators to transport massive raw materials and finished goods safely across expansive floor areas without manual intervention. The frame of the crab is constructed from rolled steel sections or welded plates to ensure maximum rigidity and stability during the movement of heavy loads. Manufacturers design these units to operate on distinct rails which enables the crab to move transversely while the main crane structure moves longitudinally. This dual motion capability ensures that every square inch of the workshop floor is accessible for loading and unloading tasks. Regular usage of these systems improves operational efficiency and reduces the time required for moving heavy items. The integration of advanced electrical systems ensures that the hoist operates smoothly and prevents sudden jerks that could damage the load. Companies that invest in high quality hoisting equipment often see a significant return on investment through increased speed and reduced labor costs. The seamless operation of the crab unit is vital for maintaining a continuous workflow in production lines where delays can lead to significant financial losses.

Crab Hoist Mechanism functionality relies on complex engineering principles to synchronize the cross travel motors with the main hoisting motor for fluid motion control. Every unit comes with a rated Lifting Capacity which dictates the maximum weight limit the equipment can safely handle during daily operations ranging from five metric tons to over one hundred metric tons. The EOT Crane Crab sits securely atop the bridge rails and houses the entire lifting assembly including the motor, brakes, and gearbox within a compact frame. Professional engineers calculate the stress factors and load distribution to ensure the crab remains stable even when lifting distinctively shaped or unbalanced objects. The design often includes four wheels that run on rails and these wheels are driven by a dedicated cross travel motor to ensure consistent speed and braking. Operators must pay close attention to the load charts to ensure they never exceed the specified limits of the machine. Overloading the system can lead to structural failure or accidents which highlights the importance of adhering to safety guidelines. Modern versions of these crabs often feature variable frequency drives which allow for soft starts and stops to protect the mechanism from wear and tear. The versatility of the crab allows it to be customized with auxiliary hoists for handling lighter loads quickly while the main hoist handles the heavy lifting. This dual functionality makes the crab an indispensable asset in versatile manufacturing sectors where load requirements change frequently throughout the day.

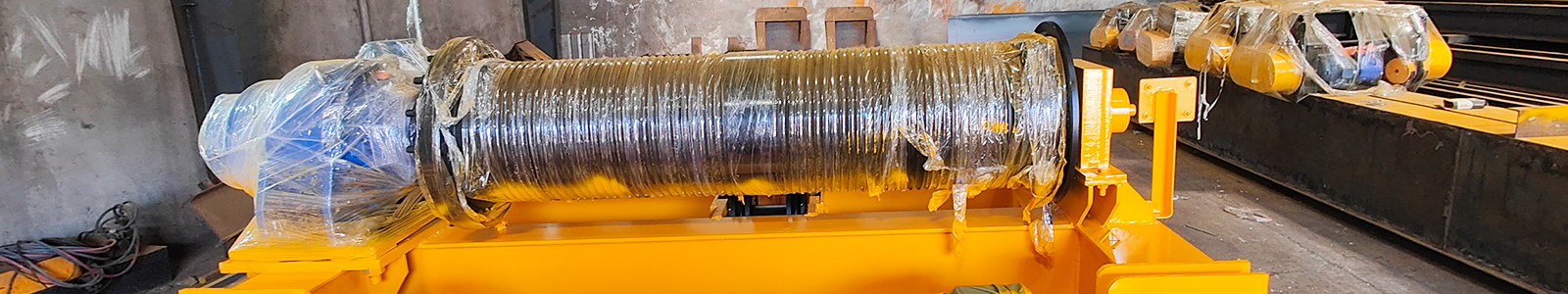

Crane Trolley Components work in unison to provide a seamless and safe lifting experience that minimizes downtime and maximizes productivity in demanding industrial settings. A central element of this assembly is the Rope Drum System which is grooved precisely to guide the steel wire rope and prevent it from overlapping or tangling during the hoisting process. Maintenance teams prioritize Gear Box Safety by inspecting the lubrication levels and gear teeth condition to prevent mechanical failures that could endanger workers or damage expensive inventory. The trolley frame supports all these components and transmits the load to the crane girders through the wheels. High quality bearings are used to reduce friction and ensure the wheels rotate smoothly under heavy loads. Safety limit switches are installed to prevent the hook from traveling too high or too low which protects the drum and the rope from damage. The braking system is another critical component that holds the load suspended in the air when the motor stops running. These brakes are designed to fail safe meaning they engage automatically if power is lost. Regular inspection of these internal parts ensures the longevity of the equipment and maintains compliance with industrial safety standards. By focusing on the quality of individual components businesses can ensure their lifting equipment remains reliable for decades. The strategic arrangement of the motor and gearbox ensures easy access for maintenance which reduces the time required for repairs and service.