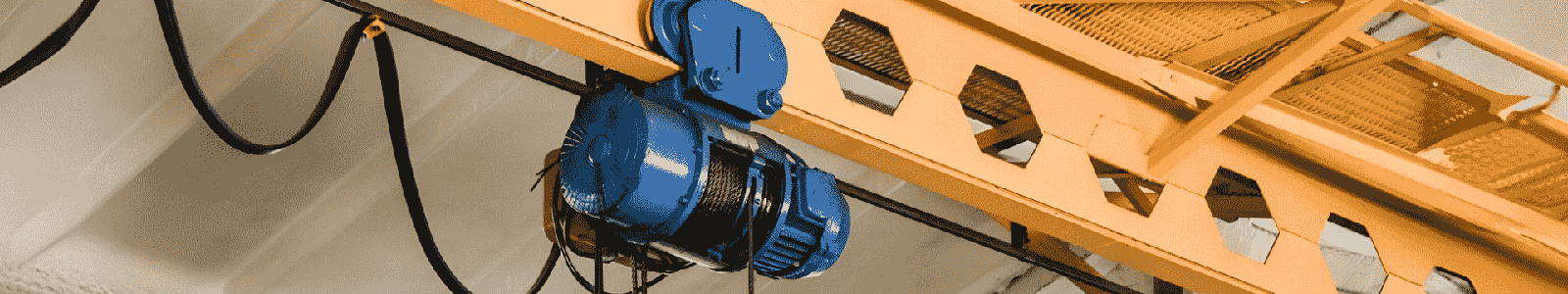

Heavy duty hoist motors are the backbone of modern industrial operations because they provide the immense force required to lift massive loads vertically without failure. These specialized engines are designed to withstand the rigorous demands of construction sites, shipping ports, and manufacturing plants where standard motors would simply burn out under the pressure. When companies invest in premium Electric crane motors, they are essentially securing the productivity of their entire facility because a single failure in the lifting mechanism can halt production lines and cause significant financial losses. It is crucial to understand that Industrial lifting equipment encompasses a wide range of machinery, yet the motor remains the most critical component that dictates the overall efficiency and speed of the operation. Engineers prioritize High torque performance when selecting these units because the initial phase of lifting a static load requires a burst of power that far exceeds the energy needed to keep the object moving once it is in the air. This specific requirement for immediate and sustained torque helps to differentiate professional grade motors from generic alternatives. Without the correct specification of power and torque, operators might face dangerous situations where the load slips or the motor overheats, leading to potential hazards for workers on the ground. Therefore, selecting the right motor is not just about purchasing hardware but about investing in the operational integrity of the business. The integration of advanced cooling systems within these motors also ensures that they can run for extended periods without thermal shutdowns, which is a common requirement in twenty-four-hour production environments where downtime is not an option.

Material handling solutions across the globe are evolving rapidly to meet the growing demand for speed and precision in logistics and warehousing sectors. To achieve this level of accuracy, modern hoist systems are often equipped with Variable speed control mechanisms that allow the operator to manage the lifting velocity with extreme fineness. This feature is particularly important when moving fragile or hazardous materials that require a soft start and a gentle stop to prevent damage or spillage during transport. The implementation of such advanced technology ensures that Reliable hoisting power is always available exactly when it is needed, providing a smooth transition from a stationary position to full lifting speed. By utilizing these sophisticated controls, facility managers can optimize the workflow and reduce the time it takes to move goods from one station to another, thereby increasing the overall throughput of the factory or warehouse. The synergy between the motor and the control drive is what creates a seamless lifting experience, reducing mechanical stress on the cables and structural components of the crane. This reduction in mechanical strain translates directly to lower energy consumption and less wear on the internal components of the machinery. Furthermore, the ability to fine tune the speed allows for better positioning of heavy components during assembly processes, such as in automotive manufacturing where engines must be placed into chassis with millimeter accuracy. Consequently, the combination of power and control is what transforms a simple lifting device into a smart tool that enhances the capability of the entire workforce.

Hoist motor safety must always be the highest priority for any organization that utilizes overhead cranes or lifting devices to move heavy items. To ensure the well-being of the workforce and the longevity of the machinery, it is essential to utilize Durable lifting gear that is rated well above the maximum expected load to account for dynamic stresses and accidental overloads. Even the most robust equipment requires regular attention, which is why Crane system maintenance is a critical practice that cannot be overlooked by safety managers. Routine inspections allow technicians to identify early signs of wear in the motor brushes, bearings, and braking systems before they develop into catastrophic failures that could endanger lives. A proactive approach to maintenance ensures that the safety features built into the motors, such as emergency brakes and thermal overload protection, function correctly when they are needed most. By adhering to a strict schedule of service and part replacement, companies can extend the operational life of their hoist motors by several years, maximizing their return on investment. It is also important to train operators on the limitations of the equipment so they do not push the motors beyond their design specifications. When safety protocols are followed and high quality components are maintained properly, the risk of accidents drops significantly. Ultimately, a safe lifting environment fosters confidence among employees and protects the valuable assets being moved, proving that safety and productivity go hand in hand in the industrial world.