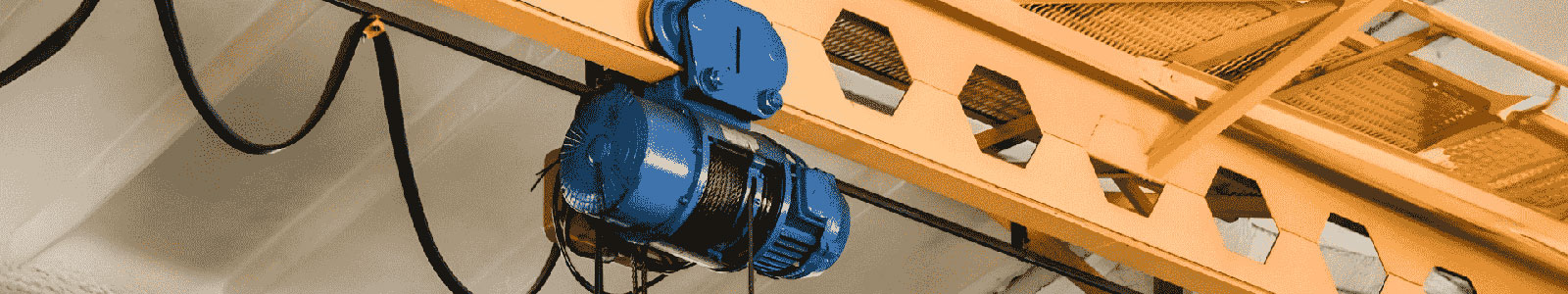

Electric Hoists are fundamental machines used in various industrial sectors to improve operational efficiency and streamline the process of moving heavy objects vertically. These devices use an electric motor to lift loads that would be impossible to move manually which helps in reducing physical strain on workers and speeding up production lines. When factories require consistent power for raising massive items they rely on Heavy Duty Lifting solutions that can withstand rigorous daily use without failure. There are two primary types of mechanisms preferred by engineers and site managers depending on their specific needs. The first type is the Wire Rope Hoist which utilizes strong steel cables wrapped around a grooved drum to perform lifts. This type is typically chosen for higher lifting heights and faster speeds in large manufacturing plants or steel mills. The second popular option is the Industrial Chain Hoist which uses a metal chain to lift the load. These are renowned for their durability and are often found in automotive workshops and assembly lines where precision and toughness are required. Choosing the correct type ensures that the workflow remains uninterrupted and productive for the business owners.

Material Handling Equipment encompasses a wide range of tools but few are as versatile and critical as the modern hoist systems found in warehouses and construction sites today. As technology advances the demand for flexibility has led to the popularity of the Portable Electric Hoist which allows users to transport the lifting mechanism to different locations within a facility easily. This portability is excellent for smaller workshops or temporary construction zones where a permanent fixture is not feasible. Modern units are designed with user safety and convenience in mind and almost every advanced model now features a Remote Control Hoist system. This allows the operator to control the lifting and lowering process from a safe distance ensuring they are not standing directly under the heavy load. Before purchasing any unit buyers must strictly evaluate the Load Capacity of the device. This specification determines the maximum weight the hoist can safely handle. Ignoring this limit can lead to catastrophic failure so it is vital to calculate the weight of the heaviest potential load and select a hoist that exceeds that number to ensure a margin of safety during operations.

Electric Hoist Maintenance is the most important aspect of owning this machinery because regular checks prevent accidents and extend the lifespan of the motor and lifting medium. A well maintained machine operates smoothly and reduces the risk of sudden breakdowns that can halt production and cost companies significant amounts of money. Technicians should inspect the brakes and limit switches frequently to confirm they function correctly under stress. In addition to the hoist itself utilizing proper Safety Lifting Gear such as slings and hooks is mandatory to secure the load effectively. The connection between the hoist and the item being lifted relies on this gear so it must be inspected for cuts or wear before every shift. By combining high quality machinery with rigorous safety protocols and using the correct accessories industries can achieve a safe working environment. Investing time in care and proper usage protocols ensures that these powerful lifting tools continue to serve their purpose effectively for many years.